Global Activities

Our activities Pacific

Our engineers fly all over the world to provide gearbox services. View our activities in Pacific. By clicking one of the links below, you will be taken to the project page with all the details of the project including pictures of our work.

Update 22-5-2014

The list below shows a selection of the projects we have done, sorted by country:

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Transporting to our workshop.

- Disassembling, cleaning and inspection of the gearbox.

- Performing of the repair constructions.

The conversion operations consists of:

- Transporting to our workshop.

- Disassembling, cleaning and inspection of the gearbox.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

The conversion operations consists of:

- Removing of the protection covers.

- Disassembling of the oil lines.

- Disassembling of the old oil pump.

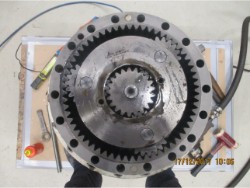

Disassembly of the gearbox

Disassembling of the gearbox took 1 day without facing major issues.

Transporting of parts to our workshop

The pinion as well as the bull gear were transported to the workshop of the shipyard.

Hoisting points needed to be welded on the ceiling of the pump motor room.

The conversion operations consists of:

- Performing of a visual inspection of the two propulsion gearboxes onboard.

- Performing of a videoscopic inspection to check the bearings of the gearbox.

- Deploying of the inspection report.

The conversion operations consists of:

- Performing of a visual inspection of all bearings and gears with the aid of an endoscope and a camera.

- Measurement of the side clearance on the bearings.

- Deploying of the inspection report.

The conversion operations consists of:

- Disassembling the complete gearbox from the platform.

- Transporting to our workshop.

- Performing of the repair constructions.

Fabrication of Emergency Pinion and on site assembly of Emergency Pinion for a cutter suction dredger.

JAHNEL KESTERMANN DWN 170

Engineering and assembly of gearbox in Australia for dredging vessel.

KA ANTRIEBSTECHNIK 013150

We performed a overhaul on three gearboxes of Jahnel Kestermann onsite.

The overhaul was performed in Papua New Guinea.

The overhaul was performed in Papua New Guinea.

JAHNEL KESTERMANN UNKNOWN

Assisiting with replacement of bearings in thrust bearing block. Also the axis needed to be exchanged.

THRUST BEARING BLOCK

Inspection and repair on LIEBHERR gearbox

LIEBHERR UNKNOWN

Inspection and repair on REGGIANA gearbox

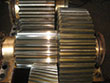

Scope of work:

- Full disassembly and cleaning of all parts.

- Inspection and report.

- Assembly and testing of the gearbox

Scope of work:

- Full disassembly and cleaning of all parts.

- Inspection and report.

- Assembly and testing of the gearbox

REGGIANA UNKNOWN

This report presents the findings of the visual inspection and oil analysis, performed on the propulsion gearbox:

- For the inspection of the gearbox, a videoscope was used. With a videoscope, clear images can be viewed

and recorded at locations with limited accessibility.

- During the inspection, an oil sample has been taken from the gearbox.

- There were no damages found on the gears.

- For the inspection of the gearbox, a videoscope was used. With a videoscope, clear images can be viewed

and recorded at locations with limited accessibility.

- During the inspection, an oil sample has been taken from the gearbox.

- There were no damages found on the gears.

RENK HSUSL-1020

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Disassembling, cleaning and inspection of the gearbox.

- Performing of the repair constructions.

CFEM 27H6SP

- Disassembling, cleaning and inspection of the gearbox.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

- Disassembling of the oil lines.

- Disassembling of the old oil pump.

RENK HSUSL-1020

Hoisting points needed to be welded on the ceiling of the pump motor room.

FLENDER 401-912-830-022-2

- Performing of a videoscopic inspection to check the bearings of the gearbox.

- Deploying of the inspection report.

HANGZHOU ADVANCE GWC 52.59-01

- Measurement of the side clearance on the bearings.

- Deploying of the inspection report.

RENK HSUSL-1020

- Transporting to our workshop.

- Performing of the repair constructions.

CFEM 27H6SP

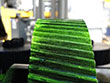

Visual inspection on every bearing and gear with our

endoscope and camera. We also inspected the oil and oil filters onsite.

endoscope and camera. We also inspected the oil and oil filters onsite.

RENK HSUSL-1020

Overhaul on two pieces gearbox CONRAD STORK 3R 560/3 onsite.

CONRAD STORK 3R 560/3