Global Activities

Our activities in the Netherlands

Our headquarters are located in The Netherlands and we serve a lot of clients in our own country. On this page a selection of gearbox projects done in The Netherlands are included. More information about the project can be viewed by clicking on the links listed below.

Inspection and repair on ZPMC NFH1610.28.C3B-00 gearbox

ZPMC FH1610.28.C3B-00

We got invited to do an inspection on a leaking gearbox in a wind turbine.

In case that the leakage is still not solved, it may take some time for the chamber on the hub side to be filled with oil again. It is therefore recommended to:

- Check the wind turbine for oil leakage again after a couple of days / after a week

- Keep inspecting the wind turbine for oil leakage for some time

If no leakage is observed after this period then the problem is solved. It has also been noted that the pitch pipe is not in line with the hollow shaft through the gearbox, it seems to be rubbing on the bottom of the hollow shaft (see appendix A, pictures 4 and 5). The pitch cilinder was also not in line with the pitch pipe. It is th

In case that the leakage is still not solved, it may take some time for the chamber on the hub side to be filled with oil again. It is therefore recommended to:

- Check the wind turbine for oil leakage again after a couple of days / after a week

- Keep inspecting the wind turbine for oil leakage for some time

If no leakage is observed after this period then the problem is solved. It has also been noted that the pitch pipe is not in line with the hollow shaft through the gearbox, it seems to be rubbing on the bottom of the hollow shaft (see appendix A, pictures 4 and 5). The pitch cilinder was also not in line with the pitch pipe. It is th

FLENDER PEAK 4280

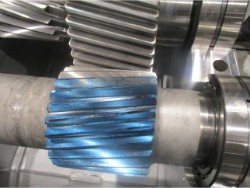

Inspection and repair on RENK gearbox

Scope of work:

- Replacement of input and output shaft;

- Replacement of radial and axial bearings;

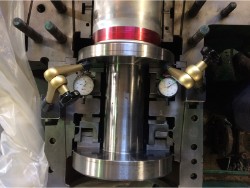

- Check of the axial clearance of all bearings;

- Assembly of the gearbox;

- Replacement of input and output shaft

- Balancing of the output shaft with new torn carrier.

- Replacement of input shaft radial and axial bearings.

- Make a blue print of the new bearings. These were found acceptable.

- Replacement of output shaft radial and axial bearings.

- Make a blue print of the new bearings. These were found acceptable.

- Adjustment of axial clearance input and output shaft by grinding the distance ring behind the axial bearings.

Scope of work:

- Replacement of input and output shaft;

- Replacement of radial and axial bearings;

- Check of the axial clearance of all bearings;

- Assembly of the gearbox;

- Replacement of input and output shaft

- Balancing of the output shaft with new torn carrier.

- Replacement of input shaft radial and axial bearings.

- Make a blue print of the new bearings. These were found acceptable.

- Replacement of output shaft radial and axial bearings.

- Make a blue print of the new bearings. These were found acceptable.

- Adjustment of axial clearance input and output shaft by grinding the distance ring behind the axial bearings.

RENK UNKNOWN

Inspection and repair on SEW R97 AM160/II2GD gearbox

SEW R97 AM160/II2GD

Inspection and repair on PIV PLC18-R11-G11-18 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Replacing bearings, seals and various small materials

- The renewal of various small materials such as gaskets, fasteners, etc.

- Assembly and adjustment

- Prepare the test stand, set up the gearbox, fill it with oil and test it for 4 hours without load

- External gear unit, degreasing, scraping, sanding and preserving in a 2-layer paint system in the existing color.

- Shipping the gearbox back to the client

Scope of work:

- Disassembly, cleaning and inspection

- Replacing bearings, seals and various small materials

- The renewal of various small materials such as gaskets, fasteners, etc.

- Assembly and adjustment

- Prepare the test stand, set up the gearbox, fill it with oil and test it for 4 hours without load

- External gear unit, degreasing, scraping, sanding and preserving in a 2-layer paint system in the existing color.

- Shipping the gearbox back to the client

PIV PLC18-R11-G11-18

Inspection and repair on PIV PLC18-R11-G11-18 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Replacing bearings, seals and various small materials

- The renewal of various small materials such as gaskets, fasteners, etc

- Assembly and adjustment

- Prepare the test stand, set up the gearbox, fill it with oil and test it for 4 hours without load

- Shipped the gearbox back to the client

Scope of work:

- Disassembly, cleaning and inspection

- Replacing bearings, seals and various small materials

- The renewal of various small materials such as gaskets, fasteners, etc

- Assembly and adjustment

- Prepare the test stand, set up the gearbox, fill it with oil and test it for 4 hours without load

- Shipped the gearbox back to the client

PIV PLC18-R11-G11-18

Inspection and repair on PHB KSZg 355 Pu gearbox

Scope of work:

- Release the gearbox

- Renew frost ring and oil seal and possibly ina - ring

- Mount the incoming coupling on site (burner set required).

- Re-align the gearbox

Scope of work:

- Release the gearbox

- Renew frost ring and oil seal and possibly ina - ring

- Mount the incoming coupling on site (burner set required).

- Re-align the gearbox

PHB KSZg 355 Pu

Inspection and repair on FLENDER T1FL-30 gearbox

We did an inspection on this gearbox and advised the client to do an overhaul, consisting of:

- Disassembly,

- Replacement of all bearings,

- Replacement of all seals

We did an inspection on this gearbox and advised the client to do an overhaul, consisting of:

- Disassembly,

- Replacement of all bearings,

- Replacement of all seals

FLENDER T1FL-30

Inspection and repair on SUMITOMO MHI PHA-9040-R3-RJLT-25 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Replacing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Replacing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

SUMITOMO MHI PHA-9040-R3-RJLT-25

Inspection and repair on WGW SC-1 gearbox

Scope of work:

- Disassembly, cleaning and inspection (2 gearboxes)

- Revision activities and deliveries

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection (2 gearboxes)

- Revision activities and deliveries

- Assembly and adjustment

- Test run with reporting

WGW SC-1

Inspection and repair on KUYPERS Koppeling gearbox

KUYPERS Koppeling

Inspection and repair on SEW R93WD-132ML4 gearbox

SEW R93WD-132ML4

Inspection and repair on FLENDER KBH 400/S/So gearbox

FLENDER KBH 400/S/So

Inspection and repair on 134-3675 Drive GP gearbox

UNKNOWN 134-3675 Drive GP

Inspection and repair on FLENDER FZH 100K gearbox

FLENDER FZH 100K

Inspection and repair on LEROY-SOMER MVA M53 G gearbox

Scope of work:

- Disassembly, cleaning, inspection

- Assembly and adjustment

- Engineering (drawing)

- Work preparation

- Delivery of bearings

- Renewal of worm gear

- Renewal of output shaft

Scope of work:

- Disassembly, cleaning, inspection

- Assembly and adjustment

- Engineering (drawing)

- Work preparation

- Delivery of bearings

- Renewal of worm gear

- Renewal of output shaft

LEROY-SOMER MVA M53 G

Inspection and repair on Flender B3-SV-7A gearbox

FLENDER B3-SV-7A

Inspection and repair on FLENDER KDN-180 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Assembly of the gearbox and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Assembly of the gearbox and adjustment

- Test run with reporting

FLENDER KDN-180

Inspection and repair on Siemens K7371-4 gearbox

SIEMENS K7371-4

Inspection and repair on FLENDER B3-SV-7A gearbox

- Disassembly, cleaning and inspection

- Bearings and seals renew

- Assembly and adjustment

- Test run with reporting

- To store the gearbox externally in a 2-layer system

- Checking the tearing for cracks

- Checking cabinet, bores (bearings) on boring table

- Cabinet, control surface and reaction plate on boring table

- Disassembly, cleaning and inspection

- Bearings and seals renew

- Assembly and adjustment

- Test run with reporting

- To store the gearbox externally in a 2-layer system

- Checking the tearing for cracks

- Checking cabinet, bores (bearings) on boring table

- Cabinet, control surface and reaction plate on boring table

FLENDER B3-SV-7A

Inspection and repair on KUMERA RD-4630-L-E1 gearbox.

Scope of work:

- Disassembly, cleaning and inspection of the gearbox

- Check interior for cracks

- Replacing bearings and seals

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection of the gearbox

- Check interior for cracks

- Replacing bearings and seals

- Test run with reporting

KUMERA RD-4630-L-E1

Inspection and repair on Exchange bearings gearbox.

Scope of work:

- Inspection of IMS-shaft and PTO-shaft;

- Replacement of bearings and seal (PTO-shaft);

- Assembly of the PTO-shaft;

- Check of the backlash of gears (PTO-shaft and IMS-shaft);

- Alignment check;

- Test run of the gearbox

Scope of work:

- Inspection of IMS-shaft and PTO-shaft;

- Replacement of bearings and seal (PTO-shaft);

- Assembly of the PTO-shaft;

- Check of the backlash of gears (PTO-shaft and IMS-shaft);

- Alignment check;

- Test run of the gearbox

GBS UNKNOWN

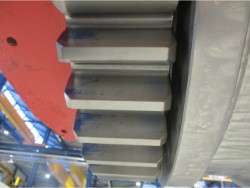

Inspection and repair on M.A.N. FLV 5.280x24,61 gearbox

M.A.N. FLV 5.280x24,61

Inspection and repair on M.A.N. Gr.2070 / 2060 gearbox

M.A.N. Gr.2070 / 2060