Global Activities

Our activities in the Netherlands

Our headquarters are located in The Netherlands and we serve a lot of clients in our own country. On this page a selection of gearbox projects done in The Netherlands are included. More information about the project can be viewed by clicking on the links listed below.

Performing a standard overhaul on four gearboxes of M.A.N. B335 x 15,7.

The standard overhaul includes:

- Overall disassembling and cleaning all of parts.

- Inspection and reporting.

- Assembling and making a test run with test run report.

The standard overhaul includes:

- Overall disassembling and cleaning all of parts.

- Inspection and reporting.

- Assembling and making a test run with test run report.

M.A.N. B335 x 15,7

We first disassembled the gearbox of Zollern in different parts.

Revision was performed according to our inspection report.

The parts were send to our workshop for complete inspection.

Assembling the gearbox again and performing a test run.

Revision was performed according to our inspection report.

The parts were send to our workshop for complete inspection.

Assembling the gearbox again and performing a test run.

ZOLLERN UNKNOWN

Performing an inspection on Motor-reductor Bauer D4A46VZ:

- Disassembling and cleaning the gearbox

- Analyzing and preparing inspection report

- Performing a test run with a test report.

- Disassembling and cleaning the gearbox

- Analyzing and preparing inspection report

- Performing a test run with a test report.

BAUER D4A46VZ

Our client had problems with gearbox WINERGY PEAB 4395.

They called us for an inspection to find the cause of the problem.

We inspected the whole gearbox and performed adjustment where needed.

They called us for an inspection to find the cause of the problem.

We inspected the whole gearbox and performed adjustment where needed.

WINERGY PEAB 4395

Performing an inspection and revision on gearbox M.A.N. D475 x 9,74:

- Overall disassembling and cleaning.

- Inspection with inspection report.

- Assembling and making a test run.

- Overall disassembling and cleaning.

- Inspection with inspection report.

- Assembling and making a test run.

M.A.N. D475 x 9,74

Performing an overhaul on gearboxes M.A.N. D475 x 9,74.

Disassembling, cleaning and inspection all of the parts.

All our findings were reported to our client.

Assembling and making a test run.

Disassembling, cleaning and inspection all of the parts.

All our findings were reported to our client.

Assembling and making a test run.

M.A.N. D475 x 9,74

We performed an inspection and overhaul on gearbox M.A.N. D475 x 974.

Overhauling includes:

Disassembling and cleaning all of the gearbox parts.

Inspection with inspection report.

Assembling and making a test run with a test run report for our client.

Overhauling includes:

Disassembling and cleaning all of the gearbox parts.

Inspection with inspection report.

Assembling and making a test run with a test run report for our client.

M.A.N. D475 x 9,74

Inspection and performing a standard overhaul on gearbox M.A.N. D475 x 9,74.

The standaard overhaul includes:

- Disassembling and cleaning all of the gearbox parts.

- Inspection with inspection report.

- Assembling the gearbox again.

- Performing a test run with a test run report.

The standaard overhaul includes:

- Disassembling and cleaning all of the gearbox parts.

- Inspection with inspection report.

- Assembling the gearbox again.

- Performing a test run with a test run report.

M.A.N. D475 x 9,74

We performed an overhaul:

Renewed the sealings and bearings.

We also performed a visual inspection on the gearbox.

At the end we made a test run with a test run report.

Renewed the sealings and bearings.

We also performed a visual inspection on the gearbox.

At the end we made a test run with a test run report.

REINTJES WAF 1562

Inspection of gearbox Lohmann & Stolterfoht.

We inspected this gearbox for any tears or damages.

We inspected this gearbox for any tears or damages.

LOHMANN & STOLTERFOHT GPV 441 S1 PG

Disassembling, inspection and cleaning of gearbox Conrad-Stork LTS-165-T-11C10. In addition, we make the inspection report.

CONRAD STORK LTS-165-T-11C10

We disassembled, inspected and cleaned gearbox CONRAD STORK LTS-165-T-11C10.

CONRAD STORK LTS-165-T-11C10

On this gearbox of Plenty we performed:

Disassembling, cleaning and inspection.

Making a complete inspection report for our client.

Assembling the gearbox again.

Disassembling, cleaning and inspection.

Making a complete inspection report for our client.

Assembling the gearbox again.

PLENTY

Performing:

- Disassembling, cleaning and inspection on gearbox Flender ZF-128-IEC-160.

- Inspection with inspection report.

- Disassembling, cleaning and inspection on gearbox Flender ZF-128-IEC-160.

- Inspection with inspection report.

FLENDER ZF-128-IEC-160

Disassembling gearbox Lohmann & Stolterfoht onsite.

We transported the gearbox to our workshop for inspection.

In our workshop we performed a visual inspection with an endoscope.

All our findings were reported to our client.

We transported the gearbox to our workshop for inspection.

In our workshop we performed a visual inspection with an endoscope.

All our findings were reported to our client.

LOHMANN & STOLTERFOHT PLANETAIRE

Inspection on gearbox Moventas includes:

- Disassembling and cleaning.

- Replacing the seals for new ones.

- Assembling and alignment of the gearbox.

- Disassembling and cleaning.

- Replacing the seals for new ones.

- Assembling and alignment of the gearbox.

MOVENTAS M3RHF70

Performing:

- Disassembling, cleaning and inspection.

- Revision according to revision proposal.

- Renew all bearings and seals.

- Assembling and making a test run with a test run report.

- Disassembling, cleaning and inspection.

- Revision according to revision proposal.

- Renew all bearings and seals.

- Assembling and making a test run with a test run report.

FLENDER FDA / FZA 100

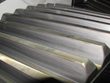

Performing on two friction shafts:

- Inspection.

- Revision.

- Inspection.

- Revision.

RHENANIA UNKNOWN

Inspection on two pieces gearboxes.

Brand: Flender.

Type: GVL 1650.

Brand: Flender.

Type: GVL 1650.

FLENDER GVL 1650

Disassembling, cleaning and inspection on gearbox Flender K-200K.

We discussed the inspection with our client.

After inspected the gearbox we made a complete inspection report.

We discussed the inspection with our client.

After inspected the gearbox we made a complete inspection report.

FLENDER K-200K

Performing a visual inspection with endoscope onsite.

Including inspection report for our client.

Including inspection report for our client.

VESTAS V52-850

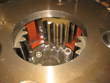

We were involved in building this gearbox of Moventas.

We gave advise and checked if everything was alright.

We gave advise and checked if everything was alright.

MOVENTAS M3RHF70

On gearbox ZPMC FH1060.35.A2.B we performed disassembling first.

We were able to clean all of the parts and performed a visual inspection.

We renewed the bearings and seals because they were damaged.

Assembling again and for a final check we performed a test run.

We were able to clean all of the parts and performed a visual inspection.

We renewed the bearings and seals because they were damaged.

Assembling again and for a final check we performed a test run.

ZPMC FH1060.35.A2B

Performing a standard overhaul on gearbox SEW SSG-5:

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

SEW SSG-5