Global Activities

Our activities in the Netherlands

Our headquarters are located in The Netherlands and we serve a lot of clients in our own country. On this page a selection of gearbox projects done in The Netherlands are included. More information about the project can be viewed by clicking on the links listed below.

- Disassembly and cleaning all of the parts.

- Inspection and reporting.

- Assembly and making a test run.

- Inspection and reporting.

- Assembly and making a test run.

CONRAD STORK 3R 355 S/3

On gearbox of ZPMC we first checked alignment of the E-engine.

After this was done, we disassembled the coupling.

We now were able to measure the axial clearance in our workshop.

Assembling of the coupling and alignment of the E-engine.

After this was done, we disassembled the coupling.

We now were able to measure the axial clearance in our workshop.

Assembling of the coupling and alignment of the E-engine.

ZPMC FH1060.24.A2A

Our client told us that gearbox ZPMC FH1650.82.C1B was leaking oil.

So we disassembled the gearbox and performed an inspection.

All our findings were reported to our client.

We could easily repair the damage, so the gearbox wasn't leaking oil anymore.

So we disassembled the gearbox and performed an inspection.

All our findings were reported to our client.

We could easily repair the damage, so the gearbox wasn't leaking oil anymore.

ZPMC FH1650.82.C1B

- Disassembling, inspecting and cleaning gearbox Hansen 511-C.

- Making a complete inspection report.

- Performing a revision according to our revision proposal.

- Assembling the gearbox and making a test run with a test run report.

- Making a complete inspection report.

- Performing a revision according to our revision proposal.

- Assembling the gearbox and making a test run with a test run report.

HANSEN 511-C

On gearbox WGW KSHK 1330 S/So we performed a preventive inspection.

We first disassembled and cleaned the gearbox.

Findings in our inspection were immediately reported to our client.

A test run was performed for a final check.

We first disassembled and cleaned the gearbox.

Findings in our inspection were immediately reported to our client.

A test run was performed for a final check.

WGW KSHK 1330 S/So

Disassembling and cleaning of the gearbox.

After that, we inspected the bearings and seals.

We made a complete inspection report for our client.

Performed a revision according to revision proposal.

Assembling the gearbox and performing a test run.

After that, we inspected the bearings and seals.

We made a complete inspection report for our client.

Performed a revision according to revision proposal.

Assembling the gearbox and performing a test run.

JAHNEL KESTERMANN AU 67

- Disassembling, cleaning and inspection on gearbox Kachelmann FVEAF-52.

- Making a complete inspection report for our client.

- Making a complete inspection report for our client.

KACHELMANN FVEAF-52

Assembling of the spacers on gearbox of Demag HVK 32 2.

Our work was performed onsite.

Our work was performed onsite.

DEMAG HVK 32 2

Delivering different parts of gearbox Rhenania ALNps43 160 Z to our client.

We also assembled the whole gearbox and replaced the bearings.

We also assembled the whole gearbox and replaced the bearings.

RHENANIA ALNps43 160 Z

Performing the repair according to our inspection report.

We first disassembled, cleaned and inspected the gearbox.

Repair includes:

- checking all of the bearings and sealings.

- assembling the gearbox again.

- Test run with a test run report.

We first disassembled, cleaned and inspected the gearbox.

Repair includes:

- checking all of the bearings and sealings.

- assembling the gearbox again.

- Test run with a test run report.

ROSSI RCI200U02V

Rhenania gearbox was damaged.

We performed an inspection and revision. This includes:

Disassembling, cleaning and inspection.

Inspection and reporting.

We talk about our findings with our client, when that was done

we assembled the gearbox and made a test run.

We performed an inspection and revision. This includes:

Disassembling, cleaning and inspection.

Inspection and reporting.

We talk about our findings with our client, when that was done

we assembled the gearbox and made a test run.

RHENANIA ALNps43-60-Z

Performing:

- Disassembling, cleaning and inspection on gearbox FLENDER SOND 175.

- Making an inspection report.

- Disassembling, cleaning and inspection on gearbox FLENDER SOND 175.

- Making an inspection report.

FLENDER SOND 175

Adjusting the axial clearance and checking the alignment of the E-engine.

Disassembling the coupling and adjusting the axial clearance in our workshop.

Assembling the coupling again and alignment on the E-engine.

Disassembling the coupling and adjusting the axial clearance in our workshop.

Assembling the coupling again and alignment on the E-engine.

ZPMC FH1060.24.A2A

First performing disassembling and cleaning on gearbox WGW KSHK 1330 S/So.

After cleaning, we did the inspection. We renewed the bearings and sealings.

We also performed a test run on the repaired gearbox.

After cleaning, we did the inspection. We renewed the bearings and sealings.

We also performed a test run on the repaired gearbox.

WGW KSHK 1330 S/So

We performed a visual inspection with an endoscope onsite.

All our findings were reported in our inspection report.

All our findings were reported in our inspection report.

ZPMC 1655.21.C2A

Our proceedings:

- Disassembling, cleaning and inspection.

- Making a complete inspection report for our client.

- Revision according to revision proposal.

We renewed all of the bearings and sealings.

When this was done, we assembled the gearbox and made a test run with a test run report.

- Disassembling, cleaning and inspection.

- Making a complete inspection report for our client.

- Revision according to revision proposal.

We renewed all of the bearings and sealings.

When this was done, we assembled the gearbox and made a test run with a test run report.

MAPRE E.2.6.100-02

Performing a standaard overhaul on gearbox Hyosung.

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Inspecting the housing for any tears.

- Checking all bearings for any damage.

- Assembling of the gearbox.

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Inspecting the housing for any tears.

- Checking all bearings for any damage.

- Assembling of the gearbox.

HYOSUNG SPH80-440KIPS

- Disassembling

- Cleaning

- Inspection with inspection report

- Assist and advise our client

- Cleaning

- Inspection with inspection report

- Assist and advise our client

FLENDER ZSK70

Disassembling and cleaning of the gearbox.

Inspection with inspection report for our client.

Inspection with inspection report for our client.

BONFIGLIOLI PRL 34003-EM65

Checking the alignment of the E-engine onsite.

Disassembling of the coupling. Checking and measuring

of the axial clearance. Adjustment of the bearing covers in our workshop.

Assembling the coupling again and alignment of the E-engine.

Disassembling of the coupling. Checking and measuring

of the axial clearance. Adjustment of the bearing covers in our workshop.

Assembling the coupling again and alignment of the E-engine.

ZPMC FH1655.21.C2A

Adjusting of the axial clearance on gearbox ZPMC FH1060.24.A2A onsite.

Disassembling of the coupling. We checked and measured the axial clearance.

Axial clearance was adjusted and we could assemble the coupling.

At the end we performed an alignment on the E-engine.

Disassembling of the coupling. We checked and measured the axial clearance.

Axial clearance was adjusted and we could assemble the coupling.

At the end we performed an alignment on the E-engine.

ZPMC FH1060.24.A2A

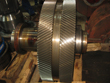

Performing a visual inspection on gearbox Lohmann & Stolterfoht GPV 441 S1 PG.

We inspected the gears for any damage and made an inspection report.

We inspected the gears for any damage and made an inspection report.

LOHMANN & STOLTERFOHT GPV 441 S1 PG

Disassembling and cleaning of gearbox WGW KSHK 1330 S/So.

After cleaning the parts, we could do our inspection work.

We renewed all bearings and repaired all sealings.

Assembling the gearbox and performing a test run.

After cleaning the parts, we could do our inspection work.

We renewed all bearings and repaired all sealings.

Assembling the gearbox and performing a test run.

WGW KSHK 1330 S/So

- Exchange bearings onsite.

- Assembling and advise our client.

- Assembling and advise our client.

FLENDER SDNK 1650

We first inspected all bearings and bores. We renewed the shafts.

We assembled the complete gearbox again and performed a

test run with a test run report for our client.

We assembled the complete gearbox again and performed a

test run with a test run report for our client.

RENK HSN-710