Global Activities

Our activities in the Netherlands

Our headquarters are located in The Netherlands and we serve a lot of clients in our own country. On this page a selection of gearbox projects done in The Netherlands are included. More information about the project can be viewed by clicking on the links listed below.

Inspection and repair on NIIGATA MGN4022V gearbox

NIIGATA MGN4022V

Inspection and repair on KESTERMAN SVO125-3-125-130-GL gearbox

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Transport

Additional work following from inspection:

- Remove the gearbox from the outside, sand, degrease and conserve

- Remove the lantern piece and E-motor frame, sand, degrease and preserve in a DTM coating

Other revision work and deliveries

- Renew the oil pump (1 pcs)

- Refresh filters (2x)

- Oil level pipe surfaces and manual retraction

- Rinse piping

- Renew the breather cap and Oil level eye

- Various fasteners

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Transport

Additional work following from inspection:

- Remove the gearbox from the outside, sand, degrease and conserve

- Remove the lantern piece and E-motor frame, sand, degrease and preserve in a DTM coating

Other revision work and deliveries

- Renew the oil pump (1 pcs)

- Refresh filters (2x)

- Oil level pipe surfaces and manual retraction

- Rinse piping

- Renew the breather cap and Oil level eye

- Various fasteners

KESTERMAN SVO125-3-125-130-GL

Inspection and repair on LOHMANN+STOLTERFOHT Pneumaflex gearbox

Scope of work:

- Remove clutch

- Disassembly the clutch at shipyard workshop

- Cleaning al parts

Replacing parts:

- Seal ring

- Seal ring

- 4x Seal ring

- 4x O-ring (Emergency bolts)

- Reassemble clutch

- Install clutch back on board

After complete reassembly of the clutch a pressure test was performed. During this pressure test, a pressure of 8 bar was applied to engage the clutch. No leaks were observed

The travel of the liners was recorded after pressurizing and after assembly of the clutch between the propulsion gearbox and the diesel engine.

Recommendations

Recomme

Scope of work:

- Remove clutch

- Disassembly the clutch at shipyard workshop

- Cleaning al parts

Replacing parts:

- Seal ring

- Seal ring

- 4x Seal ring

- 4x O-ring (Emergency bolts)

- Reassemble clutch

- Install clutch back on board

After complete reassembly of the clutch a pressure test was performed. During this pressure test, a pressure of 8 bar was applied to engage the clutch. No leaks were observed

The travel of the liners was recorded after pressurizing and after assembly of the clutch between the propulsion gearbox and the diesel engine.

Recommendations

Recomme

LOHMANN STOLTERFOHT Pneumaflex

Inspection and repair on KUMERA LD 4500-25-R-E1 gearbox

KUMERA LD 4500-25-R-E1

Inspection and repair on PHB V-1260 gearbox

The condition of both the bearings and the toothing is acceptable, however, in order to be able to switch to long and trouble-free operation, the gearbox must be cleaned internally. The running tracks in the bearings may have been caused by rotational dirt. The observed paint chips will be transported through the oil and will cause indentations in the bearings. Impressions in the bearings will lead to locally premature surface depletion and in the long term to pitting and bearing failure.

We recommend:

- Disassemble the housing in such a way that the gear unit can be thoroughly cleaned

- Pay special attention to the lubrication system so that no paint flakes remain

-

The condition of both the bearings and the toothing is acceptable, however, in order to be able to switch to long and trouble-free operation, the gearbox must be cleaned internally. The running tracks in the bearings may have been caused by rotational dirt. The observed paint chips will be transported through the oil and will cause indentations in the bearings. Impressions in the bearings will lead to locally premature surface depletion and in the long term to pitting and bearing failure.

We recommend:

- Disassemble the housing in such a way that the gear unit can be thoroughly cleaned

- Pay special attention to the lubrication system so that no paint flakes remain

-

PHB V-1260

Inspection and repair on CONRAD STORK RB 450/3H gearbox

The condition of the sand pump gearbox can be considered as good. The gears are in good condition and no major bearing damage has been observed.

Recommendations are:

- To install a breather cap with filter to prevent foreign particles from entering the gearbox

- To adjust the oil level in the gearbox according to the marks on the dipstick

- To establish a schedule of yearly visual inspections.

The condition of the sand pump gearbox can be considered as good. The gears are in good condition and no major bearing damage has been observed.

Recommendations are:

- To install a breather cap with filter to prevent foreign particles from entering the gearbox

- To adjust the oil level in the gearbox according to the marks on the dipstick

- To establish a schedule of yearly visual inspections.

CONRAD STORK RB 450/3H

Inspection and repair on WGW 355/S/SO gearbox

Large parts of the cabinet house contain places where less than 80% of the original wall thickness is present. It is therefore advisable not to reuse the cabinet.

Large parts of the cabinet house contain places where less than 80% of the original wall thickness is present. It is therefore advisable not to reuse the cabinet.

WGW 355/S/SO

Inspection and repair on BIERENS K2-A3-60 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gear box externally, 2 layers of paint

- Transport

Additional work following from inspection:

- Cupboard, internal scraping, sanding, degreasing and preserving in the Alunol

- crumbled outgoing axis the oil seal

- Apply the incoming pair of beads and locking

- Retighten spacers and spacer rings manually

- Turn bearing covers at a height i.v. boring box house

- Oil window and vent cap

- Engineering and guidance

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gear box externally, 2 layers of paint

- Transport

Additional work following from inspection:

- Cupboard, internal scraping, sanding, degreasing and preserving in the Alunol

- crumbled outgoing axis the oil seal

- Apply the incoming pair of beads and locking

- Retighten spacers and spacer rings manually

- Turn bearing covers at a height i.v. boring box house

- Oil window and vent cap

- Engineering and guidance

BIERENS K2-A3-60

Inspection and repair on HANSEN QVRD2-CUN gearbox

HANSEN QVRD2-CUN

Inspection and repair on M.A.N. FLV 5.280x24,61 gearbox

We advise:

-Make sure that the oil pump gears receive a sufficient volume flow of oil

- Change the oil after damage to the oil pump gears

- Visual inspection of the oil pump gears in three months

- Perform a visual inspection annually.

We advise:

-Make sure that the oil pump gears receive a sufficient volume flow of oil

- Change the oil after damage to the oil pump gears

- Visual inspection of the oil pump gears in three months

- Perform a visual inspection annually.

M.A.N. FLV 5.280x24,61

Inspection and repair on HANSEN 634 T gearbox

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gear box externally in a 2-layer paint

Additional work following from inspection:

- Cabinet, internal and external blasting and preserving

- Manually check inside / toothing

- Adjust the new sealing bush for incoming and outgoing Ina rings

- Refreshing the keys, adjusting ring and venting cap

- Renew fasteners with heavily retracted (hexagonal bolts)

- Work preparation and engineering

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Store the gear box externally in a 2-layer paint

Additional work following from inspection:

- Cabinet, internal and external blasting and preserving

- Manually check inside / toothing

- Adjust the new sealing bush for incoming and outgoing Ina rings

- Refreshing the keys, adjusting ring and venting cap

- Renew fasteners with heavily retracted (hexagonal bolts)

- Work preparation and engineering

HANSEN 634 T

Inspection and repair on EKATO ZFvK-10-225 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals, coupling and various small materials

- Revision activities and deliveries

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals, coupling and various small materials

- Revision activities and deliveries

- Assembly and adjustment

- Test run with reporting

EKATO ZFvK-10-225

Inspection and repair on BONFIGLIOLI MRVF-86 gearbox

BONFIGLIOLI MRVF-86

Inspection and repair on WAMPFLER K201.3/100/00 gearbox

- Disassembly, cleaning and inspection

- Renew the bearings, seals, Ina rings and VK covers

- Assemble and adjust

- Test run with reporting

- Transport

Additional work following from inspection:

- Casing, internal and external blasting and preserving

- Prepare incoming conical pinion shaft for machining, chrome-plating and namachinizing. the oil seal

- Manually inspect the inside and the teeth

- Inside work 3rd stage; Replace pinion shaft and sprocket

- Renew various small equipment, fasteners, adjusting shims and spacer

- Work preparation, guidance and engineering

- Disassembly, cleaning and inspection

- Renew the bearings, seals, Ina rings and VK covers

- Assemble and adjust

- Test run with reporting

- Transport

Additional work following from inspection:

- Casing, internal and external blasting and preserving

- Prepare incoming conical pinion shaft for machining, chrome-plating and namachinizing. the oil seal

- Manually inspect the inside and the teeth

- Inside work 3rd stage; Replace pinion shaft and sprocket

- Renew various small equipment, fasteners, adjusting shims and spacer

- Work preparation, guidance and engineering

WAMPFLER K201.3/100/00

Inspection and repair on SEW R97-A-II2GD gearbox

SEW R97-A-II2GD

Inspection and repair on HURTH HKS A 18-292 gearbox

Upon arrival, the oil had been drained from the gearbox and the cardan shaft disassembled.

After the disassembly of the coupling, the oil return channel was visible. No details were found in this, but it was blown through with compressed air and brake cleaner.

Since the gearbox was already deprived of its lubricating oil on arrival, it is not possible to retrieve it or the oil level was exceeded.

Since this gearbox is equipped with a labyrinth instead of lip seals, a too high oil level can lead to leakages.

Upon arrival, the oil had been drained from the gearbox and the cardan shaft disassembled.

After the disassembly of the coupling, the oil return channel was visible. No details were found in this, but it was blown through with compressed air and brake cleaner.

Since the gearbox was already deprived of its lubricating oil on arrival, it is not possible to retrieve it or the oil level was exceeded.

Since this gearbox is equipped with a labyrinth instead of lip seals, a too high oil level can lead to leakages.

HURTH HKS A 18-292

Inspection and repair on TACKE gearbox

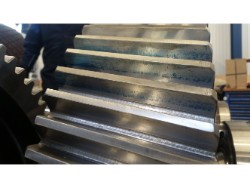

The condition of the three gearboxes can be considered as good, no indications of bearing damage have been observed and the toothing is in good condition.

Grooves or undulations were observed on both sides of the gears. This structure comes from the production process and not a sign of damage.

The condition of the three gearboxes can be considered as good, no indications of bearing damage have been observed and the toothing is in good condition.

Grooves or undulations were observed on both sides of the gears. This structure comes from the production process and not a sign of damage.

TACKE

Inspection and repair on HANSEN gearbox

We advise:

- Carry out an oil analysis in order to better assess the wear of bearings

- Perform a visual inspection annually

Elevator 3 The replacement of the ina ring and the oil seal has been successful. The elevator was also tested immediately after the work, no deviations were found.

We advise:

- Documenting the condition of the internal work in the short term by means of preventive visual inspection (2015 latest visual inspection).

We advise:

- Carry out an oil analysis in order to better assess the wear of bearings

- Perform a visual inspection annually

Elevator 3 The replacement of the ina ring and the oil seal has been successful. The elevator was also tested immediately after the work, no deviations were found.

We advise:

- Documenting the condition of the internal work in the short term by means of preventive visual inspection (2015 latest visual inspection).

HANSEN

Inspection and repair on WGW DKBH 1500/So gearbox

WGW DKBH 1500/So

Inspection and repair on ZPMC XID3-9-1,5 gearbox

ZPMC XID3-9-1,5

Inspection and repair on M.A.N. CMW 560x66,8x540-11 gearbox

M.A.N. CMW 560x66,8x540-11

Inspection and repair on M.A.N. CMW 560x66,8x540-11 gearbox

M.A.N. CMW 560x66,8x540-11

Inspection and repair on ROSSI RC-21-180-UO2A gearbox

ROSSI RC-21-180-UO2A