Global Activities

Our activities in Belgium

On this page you will find a selection of the projects we have done in Belgium. Since Belgium is only a few hours away from our headquarters in The Netherlands, we have done a lot of projects in this country. By clicking on one of the links below you can view the details of the project.

Inspection and repair on JAHNEL-KESTERMANN gearbox

JAHNEL KESTERMANN

Inspection and repair on SCOLARI RM72 gearbox

Recommendations are:

- To continue annual visual inspections and biannual oil sample analysis

- To monitor the condition of the bearings closely during the next inspection considering the criticality of this machine to factory operations.

Recommendations are:

- To continue annual visual inspections and biannual oil sample analysis

- To monitor the condition of the bearings closely during the next inspection considering the criticality of this machine to factory operations.

SCOLARI RM72

Inspection and repair on HPM 455T099056 gearbox

HPM 455T099056

Inspection and repair on FLENDER CUHW250 gearbox

- General disassembly and cleaning of all parts

- Inspect and report

- Go through the inspection report together during the work

- Assembly and testing

- General disassembly and cleaning of all parts

- Inspect and report

- Go through the inspection report together during the work

- Assembly and testing

FLENDER CUHW250

Inspection and repair on FLENDER CUHW250 gearbox

- Disassembly / assembly / test run gearbox

- Work preparation of project manager

- Delivery of new bearings and seals for input shaft

- Processing of input shaft (INA ring + spraying ceramic)

- Regrinding bore of belt pulley according to instructions

- Disassembly / assembly / test run gearbox

- Work preparation of project manager

- Delivery of new bearings and seals for input shaft

- Processing of input shaft (INA ring + spraying ceramic)

- Regrinding bore of belt pulley according to instructions

FLENDER CUHW250

Inspection and repair on KISSLING TR-680 gearbox

We advise:

- To perform a new vibration measurement after the assembly of the new outgoing spline axles (this summer) and then annually

- Perform a visual inspection and oil analysis annually.

We advise:

- To perform a new vibration measurement after the assembly of the new outgoing spline axles (this summer) and then annually

- Perform a visual inspection and oil analysis annually.

KISSLING TR-680

Inspection and repair on LIGHTNIN 85-S-20 gearbox

- Disassembly, cleaning and inspection

- Check the toothing for cracks by means of Magnaflux

- Checking axles for cracks by means of Magnaflux

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Irrigating the gearbox internally and externally and preserving it internally in Alunol

- Deliver transport

Additional work following from inspection:

- Boring cladding / verbussen

- Overhaul the incoming shaft

- Renew the 1st stage interior; Pinion and gear with conical holes

- Manually inspect the inside and the teeth

- Crumbled (hollow) shaft with Stellite on bo

- Disassembly, cleaning and inspection

- Check the toothing for cracks by means of Magnaflux

- Checking axles for cracks by means of Magnaflux

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Irrigating the gearbox internally and externally and preserving it internally in Alunol

- Deliver transport

Additional work following from inspection:

- Boring cladding / verbussen

- Overhaul the incoming shaft

- Renew the 1st stage interior; Pinion and gear with conical holes

- Manually inspect the inside and the teeth

- Crumbled (hollow) shaft with Stellite on bo

LIGHTNIN 85-S-20

Inspection and repair on FLENDER B2-SV-09-D gearbox

We advise:

- Carry out a complete overhaul of the gearbox, ie replacement of all bearings and seals

- Renew the treads of the seals

- To renew the gear of the 2nd stage as a result of pitting

- Mount an oil filter

- Clean the gearbox internally

- Perform a visual inspection and a vibration measurement annually.

We advise:

- Carry out a complete overhaul of the gearbox, ie replacement of all bearings and seals

- Renew the treads of the seals

- To renew the gear of the 2nd stage as a result of pitting

- Mount an oil filter

- Clean the gearbox internally

- Perform a visual inspection and a vibration measurement annually.

FLENDER B2-SV-09-D

Inspection and repair on LOHMANN+STOLTERFOHT GAA560WN 1500W gearbox

Conclusion of the overhaul from this gearbox are that the bearings were on his running hours, minor corrosion and little spots on the gears from running hours. The spots and marks that you see on the gears are from still standing, because of the vibration from the ship comes in the still standing gears on each other.

probably would input shaft bearings not make his running hours, that is because of the wrong storage of the spiroflex elements, with a wrong storage the Spiroflex isnít balanced any more so you get vibration on your coupling, shaft and bearings.

Recommendations

For the right storage of the spiroflex elements, GBS recommends to hor

Conclusion of the overhaul from this gearbox are that the bearings were on his running hours, minor corrosion and little spots on the gears from running hours. The spots and marks that you see on the gears are from still standing, because of the vibration from the ship comes in the still standing gears on each other.

probably would input shaft bearings not make his running hours, that is because of the wrong storage of the spiroflex elements, with a wrong storage the Spiroflex isnít balanced any more so you get vibration on your coupling, shaft and bearings.

Recommendations

For the right storage of the spiroflex elements, GBS recommends to hor

LOHMANN STOLTERFOHT GAA560WN 1500W

Inspection and repair on KESTERMAN ASVU-110-3HX-100 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Check the toothing for cracks

- Checking axles for cracks by means of Penetrant research

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Irradiate the gearbox internally and externally and preserve it, internally in Alunol

- Deliver the gearbox back to the client

Scope of work:

- Disassembly, cleaning and inspection

- Check the toothing for cracks

- Checking axles for cracks by means of Penetrant research

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Irradiate the gearbox internally and externally and preserve it, internally in Alunol

- Deliver the gearbox back to the client

KESTERMAN ASVU-110-3HX-100

Inspection and repair on SANTASALO 4L92K gearbox

Scope of work:

- Disassembly and cleaning all parts

- Visual inspection and report

- New Bearings and shaft-seals

- Renewal of various small material

- Assembly and adjusting

- Test-run with report

- Externally de-greasing and painting of the gearbox

Scope of work:

- Disassembly and cleaning all parts

- Visual inspection and report

- New Bearings and shaft-seals

- Renewal of various small material

- Assembly and adjusting

- Test-run with report

- Externally de-greasing and painting of the gearbox

SANTASALO 4L92K

Inspection and repair on LOHMANN-STOLTERFOHT GJZ 1715 gearbox

The output shaft (assembly) was overhauled in the GBS International workshop, prior to sustaining damage during transport to the vessel. Upon discovering the damage, the client returned the shaft to GBS, to assess and repair the damage.

The output shaft (assembly) was overhauled in the GBS International workshop, prior to sustaining damage during transport to the vessel. Upon discovering the damage, the client returned the shaft to GBS, to assess and repair the damage.

LOHMANN STOLTERFOHT GJZ 1715

Inspection and repair on STAHL L8126B gearbox

STAHL L8126B

Inspection and repair on MALZINE S.A. MP2-355 gearbox

MALZINE S.A. MP2-355

Inspection and repair on FLENDER SRVN 500 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renew various small equipment

- Manually inspect the inside and the teeth

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inbound pinion shaft with respect to the oil seal

- Cut out gear bore minimally

- Renew the outgoing axis

- Renew the coupling rubbers, the breather cap, the ball shut-off valves and the tappets

- Work preparation and engineering

Scope of work:

- Disassembly, cleaning and inspection

- Renew various small equipment

- Manually inspect the inside and the teeth

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inbound pinion shaft with respect to the oil seal

- Cut out gear bore minimally

- Renew the outgoing axis

- Renew the coupling rubbers, the breather cap, the ball shut-off valves and the tappets

- Work preparation and engineering

FLENDER SRVN 500

Inspection and repair on BRINKMANN PL40SSA gearbox

BRINKMANN PL40SSA

Inspection and repair on FLENDER EPMG-400 gearbox

FLENDER EPMG-400

Inspection and repair on BERSTORFF DG-1360 gearbox

BERSTORFF DG-1360

Inspection and repair on FLENDER KMP-200 gearbox

FLENDER KMP-200

Inspection and repair on KESTERMAN ASVU-110-3HX-100 gearbox

KESTERMAN ASVU-110-3HX-100

Inspection and repair on BIERENS DW15/26-Spec gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

Scope of work:

- Disassembly, cleaning and inspection

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

BIERENS DW15/26-Spec

Inspection and repair on UNKNOWN gearbox

We inspected the gearbox and performed a repair. After a succesful testrun we shipped the gearbox back to the client.

We got invited to perform a visual inspection on several gearboxes on board a ship in Germany.

We inspected all the gearboxes and reported out findings back to the client.

We inspected the gearbox and performed a repair. After a succesful testrun we shipped the gearbox back to the client.

We got invited to perform a visual inspection on several gearboxes on board a ship in Germany.

We inspected all the gearboxes and reported out findings back to the client.

GBS UNKNOWN

Inspection and repair on LOHMANN+STOLTERFOHT GJZ-1715 gearbox

GBS International was invited by to inspect and overhaul the gearbox and the attached Pneumaflex/Pneumastar clutches.

All major preparations for disassembly, as well as removing all auxiliary equipment, piping and gearbox top cover, were carried out by the Crew and TD of the client.

The shafts of the gearbox were removed from the gearbox under supervision of GBS and transported to the GBS workshop in Oud-Beijerland for further inspection.

GBS International was invited by to inspect and overhaul the gearbox and the attached Pneumaflex/Pneumastar clutches.

All major preparations for disassembly, as well as removing all auxiliary equipment, piping and gearbox top cover, were carried out by the Crew and TD of the client.

The shafts of the gearbox were removed from the gearbox under supervision of GBS and transported to the GBS workshop in Oud-Beijerland for further inspection.

LOHMANN & STOLTERFOHT GJZ-1715

Inspection and repair on FLENDER SDA160 gearbox

Scope of work:

- Visually check the cabinet for cracks, where possible.

- Visually checking the preservation internally and externally.

- Checking the holes for damage and dimensions.

- Checking the drillings for alignment deviations on the boring bench.

- Checking the flatness (fit) of the division planes

- Checking condition of the toothing of all gear transmissions

- Checking the bearings for damage phenomena.

- Checking bearing images and flank clearance of all gear transmissions.

- Checking the shaft sizes for the bearings, oil seals, gears and couplings on dimensions and damage.

- Checking the axles for sway.

- Checki

Scope of work:

- Visually check the cabinet for cracks, where possible.

- Visually checking the preservation internally and externally.

- Checking the holes for damage and dimensions.

- Checking the drillings for alignment deviations on the boring bench.

- Checking the flatness (fit) of the division planes

- Checking condition of the toothing of all gear transmissions

- Checking the bearings for damage phenomena.

- Checking bearing images and flank clearance of all gear transmissions.

- Checking the shaft sizes for the bearings, oil seals, gears and couplings on dimensions and damage.

- Checking the axles for sway.

- Checki

FLENDER SDA160

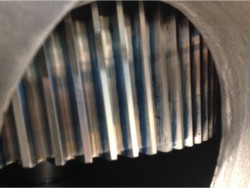

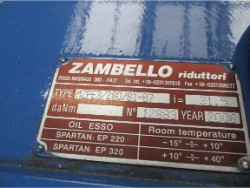

Inspection and repair on ZAMBELLO gearbox

Recommendations are:

-To continue vibration measurements and oil analysis according to the planned intervals

-To perform a visual inspection once per year

- If a significant change in oil composition, or a change in vibration levels or fault frequencies is detected, perform a visual inspection.

Recommendations are:

-To continue vibration measurements and oil analysis according to the planned intervals

-To perform a visual inspection once per year

- If a significant change in oil composition, or a change in vibration levels or fault frequencies is detected, perform a visual inspection.

ZAMBELLO UNKNOWN