Our activities in Steel, Cement & Mining Industry

Presentation of our projects in the Steel, Cement & Mining industry

On this page you will find an overview of projects we have done in the Steel, Cement & Mining industry. Our engineers flying all over the world to provide gearbox services in this industry. By clicking on one of the links below, you can view the details of the project including pictures of our work.

Performing an overhaul of two pieces gearboxes.

Overhaul includes:

- Disassembling and cleaning all of the parts.

- Inspection and reporting.

- Assembling and performing a test run with test run report.

Overhaul includes:

- Disassembling and cleaning all of the parts.

- Inspection and reporting.

- Assembling and performing a test run with test run report.

DEMAG 5213

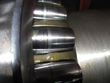

On gearbox TGW NK SCN 180 we performed an inspection.

We found the bearings had to be renewed.

Also the sealings were not alright, so we repaired them too.

We found the bearings had to be renewed.

Also the sealings were not alright, so we repaired them too.

TGW NK SCN 180

We cleaned and inspected the complete gearbox of TGW NK SCN 180.

Our findings were reported in an inspection report to our client.

Our findings were reported in an inspection report to our client.

TGW NK SCN 180

We performed and inspection on gearbox FH1650.82.C1B.

First, the gearbox was send to our workshop for inspection.

In our workshop we disassembled and cleaned the parts.

We performed the inspection and reported all our findings to our client.

Bearings and seals were renewed. The gearbox was assembled

and transported to our client again.

First, the gearbox was send to our workshop for inspection.

In our workshop we disassembled and cleaned the parts.

We performed the inspection and reported all our findings to our client.

Bearings and seals were renewed. The gearbox was assembled

and transported to our client again.

ZPMC FH1650.82.C1B

Performing an inspection and overhaul of gearbox.

FLENDER SVO 280

Disassembly, cleaning and inspection of gearbox. Preparing an inspection report and preform overhaul of gearbox.

KISSLING ER 130

Inspection and overhaul of gearbox of brand CMI / DE MALZINE.

CMI / DE MALZINE 630-H2-SP-CTR

Disassembly, cleaning and inspection of gearbox. Preparing an inspection report and preform overhaul of gearbox.

NKM 2721-24

Inspection of gearbox of brand KRUPP in Tanzania. Our customer has repaired the pinion shaft of the gearbox. The repaired pinion bearings temperature was raising to 90 degree centigrade and also running with high vibration. Our customer asked to inspect the gearbox to report its condition.

KRUPP SN11/1400/9

- Inspection and temporary repair to be able to run on 50% of it's capacity.

- Production of outer ring gear of 3 meter + planetairy gears + sun gear + new white metall bearings in 6 weeks.

- After receival of new part, we machined the outer ring gear local to fit on the other parts of the housing in an local machine shop.

- Full assembly of the gearbox.

- Commissioning on-site including aligning, vibration analyses and videoscopic checks.

- Production of outer ring gear of 3 meter + planetairy gears + sun gear + new white metall bearings in 6 weeks.

- After receival of new part, we machined the outer ring gear local to fit on the other parts of the housing in an local machine shop.

- Full assembly of the gearbox.

- Commissioning on-site including aligning, vibration analyses and videoscopic checks.

SEISA DPP 323 H

Engineering and delivery of different parts, assembly, test run and painting exterior in existing color.

LOHMANN & STOLTERFOHT GFB 35T2 1000

Visual inspection with videoscope on gearbox FLENDER CS0280/710.

FLENDER CS0280/710

- Disassembly, cleaning and inspection of gearbox.

- Preparing inspection report.

- Overhaul on gearbox.

- Preparing inspection report.

- Overhaul on gearbox.

KONE LHJ630-109 VAR. 2

Standard overhaul on gearbox. Disassembling, cleaning,

inspection

of gearbox DEMAG 5213, preparing inspection report and overhaul.

of gearbox DEMAG 5213, preparing inspection report and overhaul.

DEMAG 5213

- Disassembly, cleaning and inspection on gearbox SAWA V2000 / 31,5L.

- Going through the inspection report.

- Overhaul on the gearbox.

- Going through the inspection report.

- Overhaul on the gearbox.

SAWA V2000 / 31,5L

- Full inspection of damaged gearbox and cause analyses.

- Full repair of this gearbox including Voith couplings.

- Full repair of this gearbox including Voith couplings.

KUMERA KFM3125 LB E2

- Disassembly, cleaning and inspection of gearbox.

- Preparing inspection report.

- Preparing inspection report.

SEW D100

Overhaul of gearbox Hansen SKZN-66-C-20-UR.

The bearings of the gearbox were damaged and the gearbox has run without oil for some time.

We disassembled, cleaned and inspected the gearbox.

After inspecting the gearbox, we renewed all the bearings and checked all sealings.

We assembled the gearbox and performed a test run with a test run report.

The bearings of the gearbox were damaged and the gearbox has run without oil for some time.

We disassembled, cleaned and inspected the gearbox.

After inspecting the gearbox, we renewed all the bearings and checked all sealings.

We assembled the gearbox and performed a test run with a test run report.

HANSEN SKZN-66-C-20-UR

Overhaul of complete broken gearbox. New internals in 2.5 week time.

FLENDER H2SH SIZE 24

- Disassembly, cleaning and inspection of gearbox.

- Preparing inspection report.

- Preparing inspection report.

KONE HSC-32252E/FY-500

Several companies allready have measured the noise and vibrations of this KRUPP gearbox. We offered not only to measure the installation, but promised to solve the problem. After checking and correcting the alignment, we examined the relation between the axial movement of the input shaft and the noise production of the dryer drum. We are now proposing a modification of the installation.

KRUPP NR4391

- Inspection and measurements in Dibba, U.A.E.

- Production of a case hardend pinion of 2 meters long.

- Assembly of gearbox and testrun.

- Production of a case hardend pinion of 2 meters long.

- Assembly of gearbox and testrun.

FLENDER DMGH22

- Inspection and overhaul of gearbox.

- Performing a inspection including non-destructive research of the bearings, planetary wheels and other internals.

- Performing a rooth coarse analyse and determining repair proposal.

- Repair of all neccessary parts and test run in our facility.

- Performing a inspection including non-destructive research of the bearings, planetary wheels and other internals.

- Performing a rooth coarse analyse and determining repair proposal.

- Repair of all neccessary parts and test run in our facility.

RENK PA63p

Performing an inspection, repair and test run of this Hansen gearbox SKZN-46-C-16-UR.

HANSEN SKZN-46-C-16-UR

The dismantling of the gearbox and inspecting the gearbox.

GBS made an overhaul proposal and the customer agreed.

The gearbox made a succesfull testrun after the overhaul.

GBS made an overhaul proposal and the customer agreed.

The gearbox made a succesfull testrun after the overhaul.

FLACHGETRIEBE D22