Our activities in the Maritime Industry

Presentation of our Maritime projects

On this page you will find an overview of projects we have done in the maritime industry, dredging is excluded, we have a separate category for that. If you click on one of the links below, you will see all the details of the project.

We performed an inspection and revision on HALBERG RTDB 1000-76x2 106364.

We performed an inspection and revision on FLENDER gearbox G1VY size 670.

We performed an inspection and revision on gearbox ASUG GVE 800x3,75-800x0,4.

The conversion operations consists of:

Performing of a visual inspection of the gearbox.

Deploying of the inspection report.

We performed an inspection and revision on gearbox ASUG GDG 1265x8,9.

The conversion operations consists of:

Performing of a visual inspection of the gearbox.

Deploying of the inspection report.

Stop point.

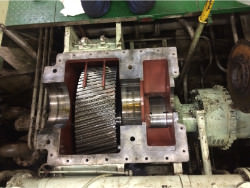

We performed an inspection and repair on a gearbox LOHMANN & STOLTERFOHT GCS850.

We performed an inspection and revision on FLENDER gearbox G1VY.

We performed an inspection and repair on a gearbox RENK AWS-315.

Disassembly on board

- All piping and electric connections were removed.

- Hydraulic pump for the rudder control was removed.

- The input shaft coupling was disconnected from the main engine.

The conversion operations consists of:

- Performing of a visual inspection of the propulsion gearbox onboard.

- Performing of a videoscopic inspection to check the gears and the bearings.

- Deploying of the inspection report.

The conversion operations consists of:

- Performing of a visual inspection of the propulsion gearbox onboard.

- Performing of a videoscopic inspection to check the gears and the bearings.

- Deploying of the inspection report.

The conversion operations consists of:

- Disassembling, cleaning and inspection of the gearbox.

- Performing of the repair constructions.

- Deploying of the inspection report.

The conversion operations consists of:

- Performing of a visual inspection of the two propulsion gearboxes onboard.

- Performing of a videoscopic inspection to check the bearings of the gearbox.

- Deploying of the inspection report.

The conversion operations consists of:

- Performing of a visual inspection of the two propulsion gearboxes onboard.

- Performing of a videoscopic inspection to check the bearings of the gearbox.

- Deploying of the inspection report.

The conversion operations consists of:

- Performing of a visual inspection of all bearings and gears.

- Measurement of the bearings for side clearances.

- Inspection of the oil filters.

The conversion operations consists of:

- Performing of a visual inspection.

- Performing of the repair constructions.

- Deploying of the inspection report.

The conversion operations consists of:

- Performing of a visual inspection of all bearings and gears with the aid of an endoscope and a camera.

- Measurement of the side clearance on the bearings.

- Deploying of the inspection report.

The conversion operations consists of:

- Disassembling and ispection of the gearbox on location.

- Renewing of the axial-radial bearings of the input hollow shaft.

- Refacing bearing surfaces of the hollow shaft.

The conversion operations consists of:

- Performing a visual inspection.

- Controlling the first intermediate shaft for micro pitting.

- Performing of a videoscopic inspection.

- Bringing back of the oil level under the maximum allowed.

We performed an inspection and repair on a gearbox VALMET S1G-280ARIT1F GEARBOX.

VALMET S1G-280ARIT1F

We performed an inspection and overhaul on a gearbox WGW 280-S-50.

The conversion operations consists of:

-Complete overhaul of the winches and pulley blocks.

-Composing inspection report and advice.

-Disassembly of the pulley blocks.

-Transport to GBS.

-Manufacture of certified shafts, bearings, couplings, chains and gears (Lloyd's classification).

-Applying a two-layer seawater-resistant coating.

The conversion operations consists of:

-Complete overhaul of the winches and pulley blocks.

-Composing inspection report and advice.

-Disassembly of the pulley blocks.

-Transport to GBS.

-Manufacture of certified shafts, bearings, couplings, chains and gears (Lloyd's classification).

-Applying a two-layer seawater-resistant coating.

WGW 280-S-50

We performed an inspection and revision on HALBERG RTDB 1000-76x2 106364.

HALBERG RTDB 1000-76x2

We performed an inspection and revision on FLENDER gearbox G1VY size 670.

FLENDER G1VY size 670

We performed an inspection and revision on gearbox ASUG GVE 800x3,75-800x0,4.

The conversion operations consists of:

Performing of a visual inspection of the gearbox.

Deploying of the inspection report.

ASUG GVE 800x3,75-800x0,4

We performed an inspection and revision on gearbox ASUG GDG 1265x8,9.

The conversion operations consists of:

Performing of a visual inspection of the gearbox.

Deploying of the inspection report.

Stop point.

ASUG GDG 1265x8,9

We performed an inspection and repair on a gearbox LOHMANN & STOLTERFOHT GCS850.

LOHMANN & STOLTERFOHT GCS850

We performed an inspection and revision on FLENDER gearbox G1VY.

FLENDER G1VY

We performed an inspection and repair on a gearbox RENK AWS-315.

RENK CSCF-100AWS-315

- Hydraulic pump for the rudder control was removed.

- The input shaft coupling was disconnected from the main engine.

RHENANIA AWNG 45/50S

- Performing of a videoscopic inspection to check the gears and the bearings.

- Deploying of the inspection report.

VALMET MH1BC-915+P500

- Performing of a videoscopic inspection to check the gears and the bearings.

- Deploying of the inspection report.

LOHMANN & STOLTERFOHT GCS-900

- Performing of the repair constructions.

- Deploying of the inspection report.

FLENDER B3 DH 10 C

- Performing of a videoscopic inspection to check the bearings of the gearbox.

- Deploying of the inspection report.

HANGZHOU ADVANCE GWC 52.59-01

- Performing of a videoscopic inspection to check the bearings of the gearbox.

- Deploying of the inspection report.

HANGZHOU ADVANCE GWC 52.59-01

- Measurement of the bearings for side clearances.

- Inspection of the oil filters.

RENK HSUSL-1020

- Performing of the repair constructions.

- Deploying of the inspection report.

LOHMANN & STOLTERFOHT GCS-900

This presents the findings of the visual inspection, vibration analysis and shaft

alignment check, performed on the generator gearbox of Asug. For the

inspection of the gears and bearings of the gearbox, a videoscope was used.

Clear images can be viewed and recorded by a videoscope at locations with

limited accessibility.

alignment check, performed on the generator gearbox of Asug. For the

inspection of the gears and bearings of the gearbox, a videoscope was used.

Clear images can be viewed and recorded by a videoscope at locations with

limited accessibility.

ASUG STG-2-900

- Measurement of the side clearance on the bearings.

- Deploying of the inspection report.

RENK HSUSL-1020

Performing on site:

Visual inspection on gearbox Renk hsusl-1020.

Inspection on the oil filters.

Visual inspection on gearbox Renk hsusl-1020.

Inspection on the oil filters.

RENK HSUSL-1020

- Renewing of the axial-radial bearings of the input hollow shaft.

- Refacing bearing surfaces of the hollow shaft.

RENK TACKE HSU-800D

- Controlling the first intermediate shaft for micro pitting.

- Performing of a videoscopic inspection.

- Bringing back of the oil level under the maximum allowed.

LOHMANN & STOLTERFOHT GUS450