Our activities in Chemical Industry

Presentation of our projects in the Chemical industry

On this page you will find a selection of gearbox related projects we have done in the chemical industry for clients all over the world. If you want to know more about the project, you can click the link for more information. Pictures are also added to the project page.

Performing a standard overhaul on gearbox Lightnin Serie 70 & 80. This includes:

- Disassembling and cleaning the gearbox.

- Visual inspection for any tears or leaks.

- Checking for the condition of the gears.

- Assembling the gearbox again.

- Disassembling and cleaning the gearbox.

- Visual inspection for any tears or leaks.

- Checking for the condition of the gears.

- Assembling the gearbox again.

LIGHTNIN Serie 70 & 80

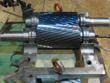

Overhaul on gearbox Lightnin 88S - 75.

Disassembling and cleaning the gearbox.

Visual inspection all of the parts for any tears or damages.

Disassembling and cleaning the gearbox.

Visual inspection all of the parts for any tears or damages.

LIGHTNIN 88S - 75

Performing a standard overhaul on gearbox SEW SF-90-EXD.

Our findings were reported to our client.

We renewed all of the bearings and sealings and assembled the gearbox again.

A test run is our final step to check if everything is alright.

Our findings were reported to our client.

We renewed all of the bearings and sealings and assembled the gearbox again.

A test run is our final step to check if everything is alright.

SEW SF-90-EXD

Performing an overhaul on gearbox Chemineer 2-HTN-3.

The overhauling contains:

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Assembly and making a test run.

The overhauling contains:

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Assembly and making a test run.

CHEMINEER 2-HTN-3

Performing a standard overhaul on gearbox Kachelmann AH-50A.

Renewed all gear sets.

Overhauling includes:

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Assembling and test run with test run report.

Renewed all gear sets.

Overhauling includes:

- Disassembling and cleaning all of the parts.

- Inspection with inspection report.

- Assembling and test run with test run report.

KACHELMANN AH-50A

First we disassembled gearbox of Kachelmann, type AH-50A.

We cleaned the gearbox.

For our visual inspection we used our endoscope, including reporting of the two gearboxes.

At last, we assembled and made a test run.

We cleaned the gearbox.

For our visual inspection we used our endoscope, including reporting of the two gearboxes.

At last, we assembled and made a test run.

KACHELMANN AH-50A

Performing a standard overhaul on gearbox Chemineer 4-HTN-5.

Overhauling contains:

- Complete disassembly and cleaning all of the parts.

- Inspection and reporting.

- Assembly and making a test run.

Overhauling contains:

- Complete disassembly and cleaning all of the parts.

- Inspection and reporting.

- Assembly and making a test run.

CHEMINEER 4-HTN-5

The overhauling contains:

- Complete disassembly and cleaning all of the parts

- Inspection and reporting

- Assembly and making a test run.

- Complete disassembly and cleaning all of the parts

- Inspection and reporting

- Assembly and making a test run.

CHEMINEER 4-HTN-5

- Disassembling, cleaing and inspecting the gearbox.

- Performing a test run and reporting on gearbox Bierens AB-36,5 spec.

- Performing a test run and reporting on gearbox Bierens AB-36,5 spec.

BIERENS AB-36,5-spec

Performing:

- Disassembling, cleaning and inspeting gearbox BIERENS-K2-A3-55.

- Setting up a complete inspection report.

- Disassembling, cleaning and inspeting gearbox BIERENS-K2-A3-55.

- Setting up a complete inspection report.

BIERENS K2A3-55

- Disassembling, cleaing and inspecting the gearbox.

- Performing a test run and reporting on gearbox Bierens AB-36,5 spec.

- Performing a test run and reporting on gearbox Bierens AB-36,5 spec.

BIERENS AB-36,5 spec.

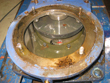

On gearbox TGW 107 we performed and inspection and revision.

We first disassembled and cleaned all of the parts.

After that, we could do our inspection on all of the parts.

Our client was invited to report our findings.

We found that the bearings were damaged, so we had to

repair them. After repairing we were able to perform the test run.

We first disassembled and cleaned all of the parts.

After that, we could do our inspection on all of the parts.

Our client was invited to report our findings.

We found that the bearings were damaged, so we had to

repair them. After repairing we were able to perform the test run.

TGW 107

Our engineers performed a visual inspection on gearbox ABB DL SL 1800 S8.

First we disassembled and cleaned the gearbox. Visual

inspection was possible now. All our findings were reported to our client.

First we disassembled and cleaned the gearbox. Visual

inspection was possible now. All our findings were reported to our client.

ABB DP SL 1800 S8

- Revision/Assembling.

- Inspection for any tears.

- Inspection all of the bearings.

- Making a full inspection report and a test run with a test run report.

- Inspection for any tears.

- Inspection all of the bearings.

- Making a full inspection report and a test run with a test run report.

FLENDER 118F - 13,5

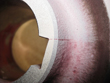

We fully inspected this gearbox of Rademakers.

We first performed a test run for eight hours long.

The gearbox was leaking, our findings were reported to our client.

Repaired the damage and renewed the bearings.

Making a final test run to make sure the gearbox is repaired.

We first performed a test run for eight hours long.

The gearbox was leaking, our findings were reported to our client.

Repaired the damage and renewed the bearings.

Making a final test run to make sure the gearbox is repaired.

RADEMAKERS 2043758

- Exchanging 1 piece quadrant coupling with existing quadrant coupling.

- Bores and keyway are machined conform existing quadrant couplings.

- Bores and keyway are machined conform existing quadrant couplings.

BIERENS K2A3-80

We performed a standard overhaul on gearbox Leistritz ZSE-40-HPC-1200.

Renewed all of the bearings and sealings.

(Dis)assembling and alignment onsite.

Renewed all of the bearings and sealings.

(Dis)assembling and alignment onsite.

LEISTRITZ ZSE-40-HPC-1200

Inspection of gearbox Lightnin LS-75. Revision according to revision proposal.

Renewed the bearings and sealings.

Assembling of the gearbox.

Renewed the bearings and sealings.

Assembling of the gearbox.

LIGHTNIN LS-75

Performing:

- Disassembling, cleaning and inspection on gearbox Kumera RB 3355.

- Making a complete inspection report for our client.

- Disassembling, cleaning and inspection on gearbox Kumera RB 3355.

- Making a complete inspection report for our client.

KUMERA RB 3355

Performing:

- Disassembling, cleaning and inspection on gearbox DAVID BROWN R5F610.

- Making an inspection report.

- Assembling and revision according revision proposal.

- Performing a test run with a test run report.

- Disassembling, cleaning and inspection on gearbox DAVID BROWN R5F610.

- Making an inspection report.

- Assembling and revision according revision proposal.

- Performing a test run with a test run report.

DAVID BROWN R5F610

Inspecting gearbox Buhler EX-141 E/325 with an endoscope.

We made an inspection report of all the findings and presented it to our client.

We made an inspection report of all the findings and presented it to our client.

BUHLER EX-141 E/325

Performing:

- Disassembling, cleaning and inspection on gearbox BIERENS-K2A3-80. - Making a complete inspection report.

- Disassembling, cleaning and inspection on gearbox BIERENS-K2A3-80. - Making a complete inspection report.

BIERENS K2A3-80

Performing an inspection on Motor-reductor Bauer D4A46VZ:

- Disassembling and cleaning the gearbox

- Analyzing and preparing inspection report

- Performing a test run with a test report.

- Disassembling and cleaning the gearbox

- Analyzing and preparing inspection report

- Performing a test run with a test report.

BAUER D4A46VZ

Performing a test run with a test run report on gearbox Bierens AB-36,5 spec.

BIERENS AB-36,5 spec.

Disassembling and cleaning of gearbox SEW RF100-L6200.

Renewed all of the bearings and sealings.

We also checked and renewed small parts of the gearbox, like

the mountings. At the end we performed a last test run, before

the gearbox will be delivered at our client.

Renewed all of the bearings and sealings.

We also checked and renewed small parts of the gearbox, like

the mountings. At the end we performed a last test run, before

the gearbox will be delivered at our client.

SEW RF100-L6200