Our activities in Chemical Industry

Presentation of our projects in the Chemical industry

On this page you will find a selection of gearbox related projects we have done in the chemical industry for clients all over the world. If you want to know more about the project, you can click the link for more information. Pictures are also added to the project page.

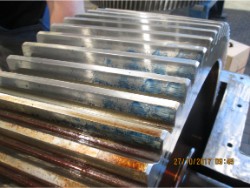

Inspection and repair on FLENDER SRVN 500 gearbox

Scope of work:

- Disassembly, cleaning and inspection

- Renew various small equipment

- Manually inspect the inside and the teeth

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inbound pinion shaft with respect to the oil seal

- Cut out gear bore minimally

- Renew the outgoing axis

- Renew the coupling rubbers, the breather cap, the ball shut-off valves and the tappets

- Work preparation and engineering

Scope of work:

- Disassembly, cleaning and inspection

- Renew various small equipment

- Manually inspect the inside and the teeth

- Assembly and adjustment

- Test run with reporting

- Store the gearbox externally in a 2-layer paint system

Additional work following from inspection:

- Protect the gear box internally in Alunol

- Inbound pinion shaft with respect to the oil seal

- Cut out gear bore minimally

- Renew the outgoing axis

- Renew the coupling rubbers, the breather cap, the ball shut-off valves and the tappets

- Work preparation and engineering

FLENDER SRVN 500

Inspection and repair on ITAYA GR CH204 gearbox

ITAYA GR CH204

Inspection and repair on FLENDER EPMG-400 gearbox

FLENDER EPMG-400

Inspection and repair on BERSTORFF DG-1360 gearbox

BERSTORFF DG-1360

Inspection and repair on KESTERMAN ASVU-110-3HX-100 gearbox

KESTERMAN ASVU-110-3HX-100

Inspection and repair on POMINI FARREL 9FC-MU gearbox

Scope of work:

- Disassembly, cleaning and inspection of gearbox

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Conserve the gear box externally in 2 layers

Scope of work:

- Disassembly, cleaning and inspection of gearbox

- Renewing bearings, seals and various small materials

- Assembly and adjustment

- Test run with reporting

- Conserve the gear box externally in 2 layers

POMINI FARREL 9FC-MU

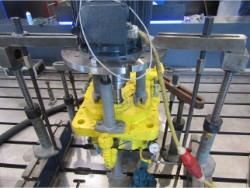

Inspection and repair on FLENDER SDN 450 gearbox

During the inspection, a few bolt holes of the aluminum oil cooler have been rotated. This was solved on the spot by providing all four bolt holes with Helicoils. The oil cooler was then tested by raising the water pressure again, no leakages were observed.

We advise:

- Continue the vibration measurements and visual inspections at the same interval

- If a change in vibration levels, or error frequencies is detected, perform a visual inspection again

- At a subsequent revision, install a filter element in the lubrication system of the Flender KLN 250

- Adjust the axial clearance of the flexible coupling correctly.

We advise:

- Continue the vibration measurements and visual inspections at the same interval

- If a change in vibration levels, or error frequencies is detected, perform a visual inspection again

- At a subsequent revision, install a filter element in the lubrication system of the Flender KLN 250

- Adjust the axial clearance of the flexible coupling correctly.

FLENDER SDN 450

Inspection and repair on JAHNEL-KESTERMANN CSBV 225 L gearbox

JAHNEL KESTERMANN CSBV 225 L

Inspection and repair on FLENDER T1FL-30 gearbox

We did an inspection on this gearbox and advised the client to do an overhaul, consisting of:

- Disassembly,

- Replacement of all bearings,

- Replacement of all seals

We did an inspection on this gearbox and advised the client to do an overhaul, consisting of:

- Disassembly,

- Replacement of all bearings,

- Replacement of all seals

FLENDER T1FL-30

Inspection and repair on SEW R93WD-132ML4 gearbox

SEW R93WD-132ML4

Inspection and repair on FLENDER FZH 100K gearbox

FLENDER FZH 100K

Inspection and repair on FLENDER B3-SV-7A gearbox

- Disassembly, cleaning and inspection

- Bearings and seals renew

- Assembly and adjustment

- Test run with reporting

- To store the gearbox externally in a 2-layer system

- Checking the tearing for cracks

- Checking cabinet, bores (bearings) on boring table

- Cabinet, control surface and reaction plate on boring table

- Disassembly, cleaning and inspection

- Bearings and seals renew

- Assembly and adjustment

- Test run with reporting

- To store the gearbox externally in a 2-layer system

- Checking the tearing for cracks

- Checking cabinet, bores (bearings) on boring table

- Cabinet, control surface and reaction plate on boring table

FLENDER B3-SV-7A

All white metal bearings and shafts are badly damaged.

The cause for this is; the lubrication between the shaft and the bearing was inadequate.

This could be due to;

- Too much water in the oil (a lot of corrosion has been observed)

- Incorrect start-up procedure during start-up, as a result of which there is an insufficient oil film between shaft and bearing during start-up

- A combination of the above

The cause for this is; the lubrication between the shaft and the bearing was inadequate.

This could be due to;

- Too much water in the oil (a lot of corrosion has been observed)

- Incorrect start-up procedure during start-up, as a result of which there is an insufficient oil film between shaft and bearing during start-up

- A combination of the above

DAVID BROWN HSN-250-SRG

We performed an inspection and repair on a gearbox CHEMINEER 7-HTN-100.

CHEMINEER 7-HTN-100

We performed an inspection and repair on a EKATO gearbox.

EKATO UNKNOWN

We performed an inspection and revision on FLENDER gearbox.

FLENDER SDOS 250

We performed an inspection and repair on a gearbox Jahnel Kestermann ASVU-110-3HX-100.

JAHNEL KESTERMANN ASVU-110-3HX-100

We performed an inspection and repair on a gearbox CHEMINEER 6-XHTN-60.

CHEMINEER 6-XHTN-60

We performed an inspection and repair on a EKATO EKF-3V-280-660-KR gearbox.

EKATO UNKNOWN

We performed an inspection and revision on FLENDER gearbox.

FLENDER SDOS 360

We performed an inspection and repair on a gearbox HANSEN 634 T.

HANSEN 634 T

We performed an inspection and repair on a gearbox HANSEN NG56K-AN-71.

HANSEN NG56K-AN-71

We performed an inspection and repair on a gearbox HANSEN QVRB2L-CUN-8.

HANSEN QVRB2L-CUN-8

We performed an inspection and repair on a gearbox HANSEN QVRE2X-CUN.

HANSEN QVRE2X-CUN

We performed an inspection and revision on gearbox of ITAYA GR CH204.

ITAYA GR CH204