News items of GBS Gearbox Services international

News items

GBS inspecteert 2 baggerschepen met videoscoopLees meer

Quick scan na reparatie voor langere levensduur tandwielkastLees meer

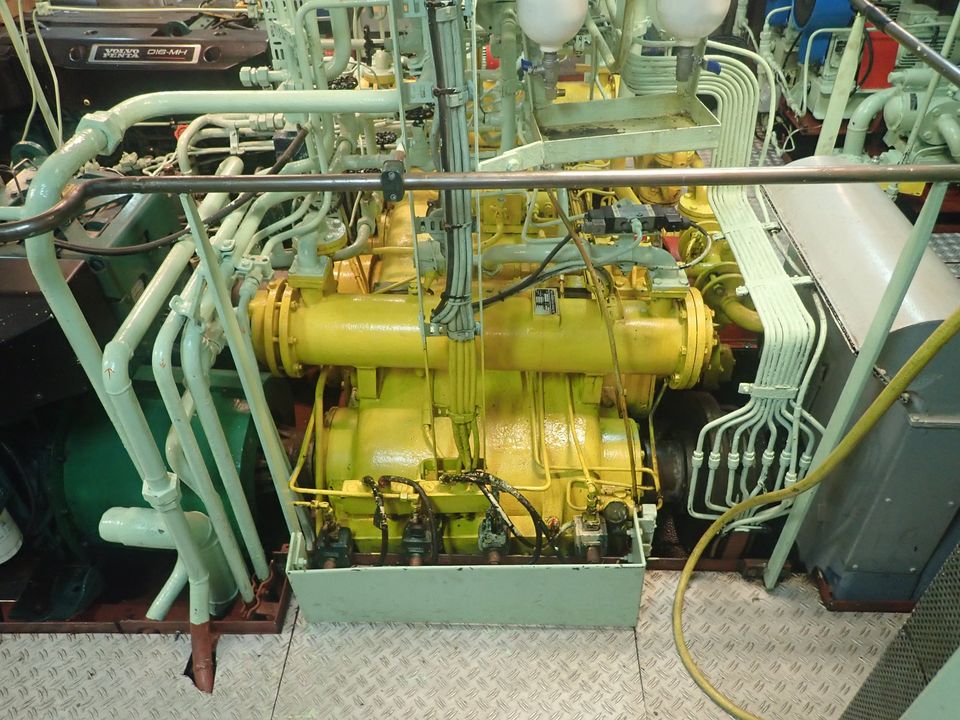

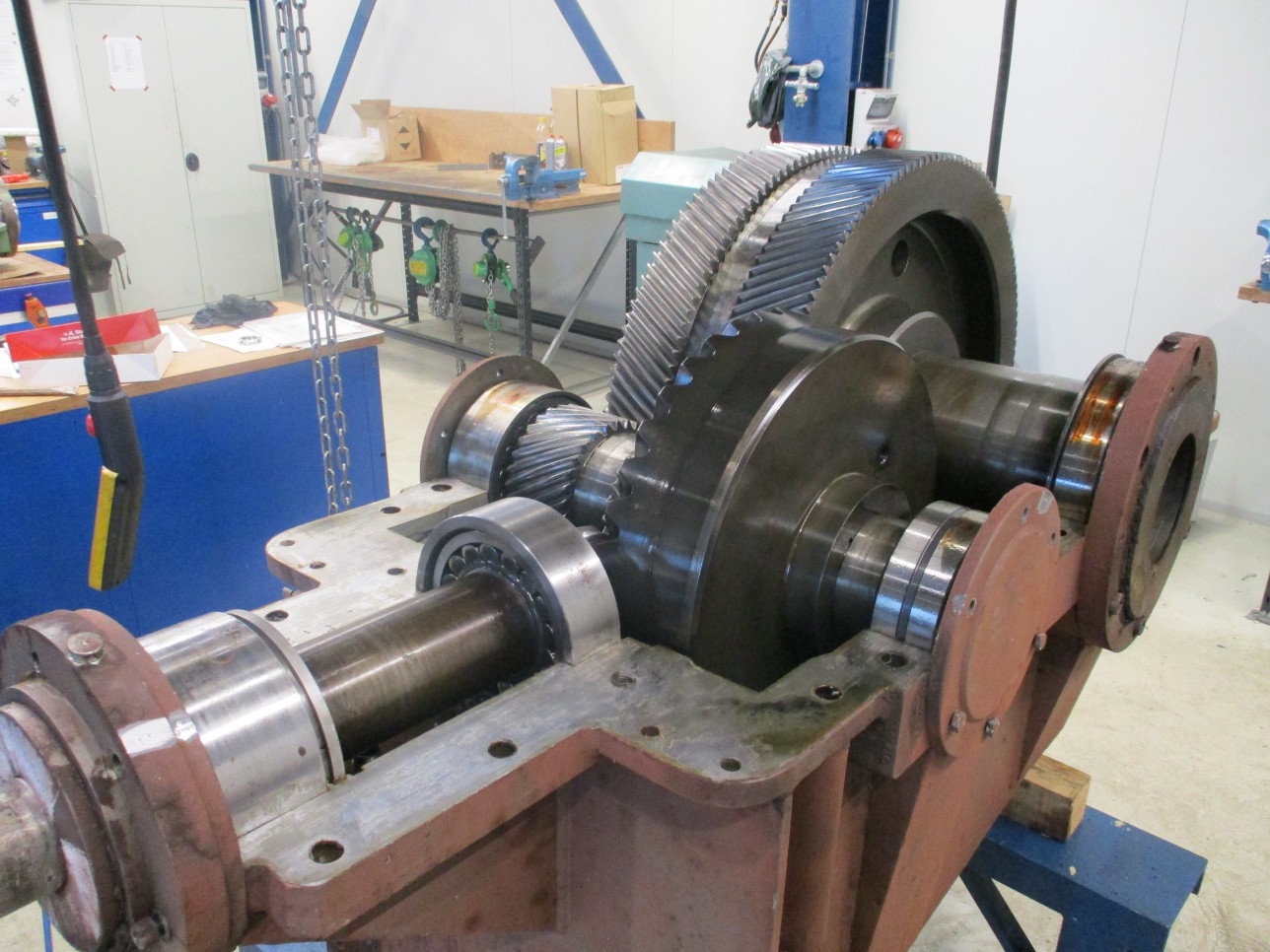

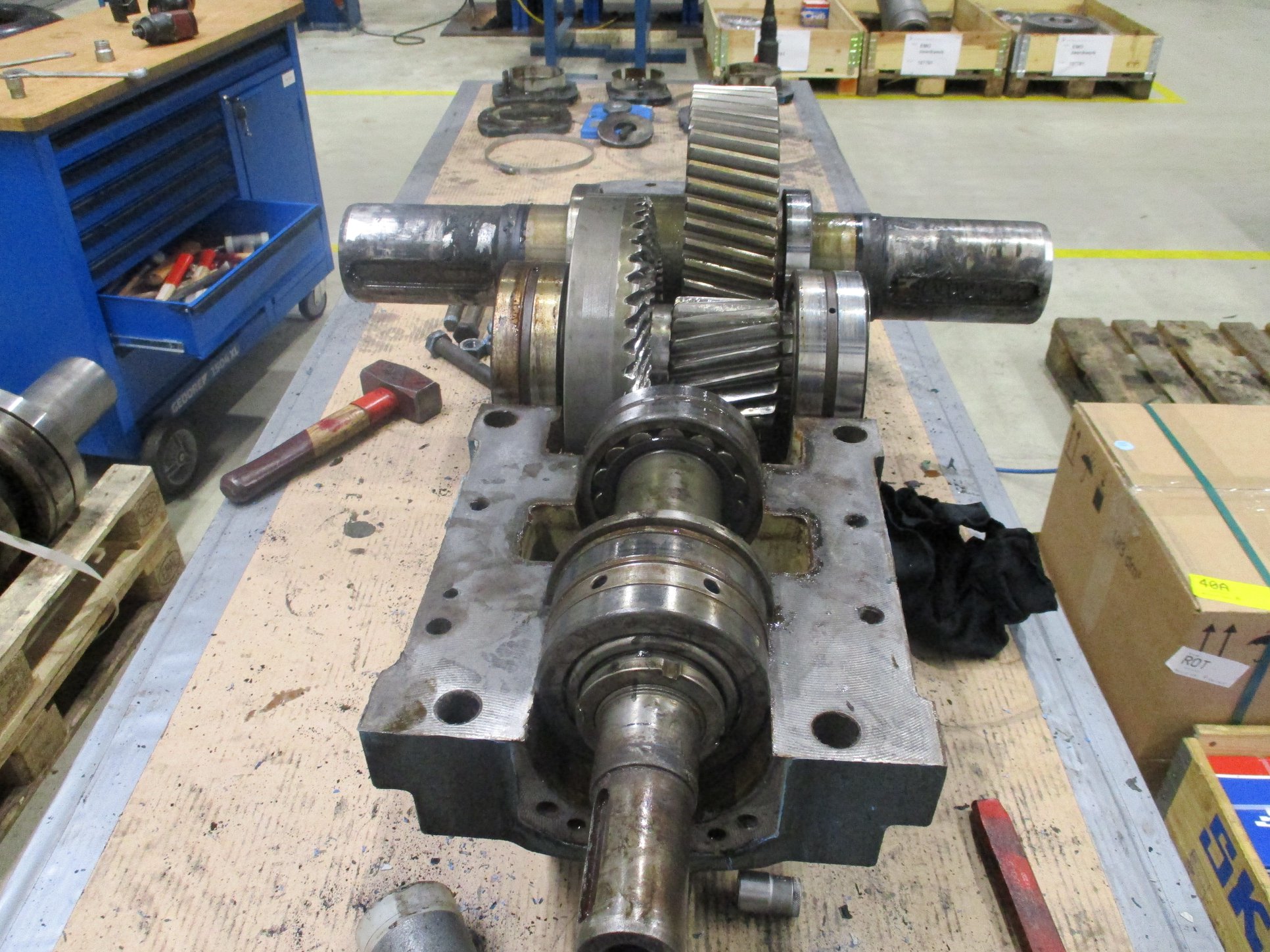

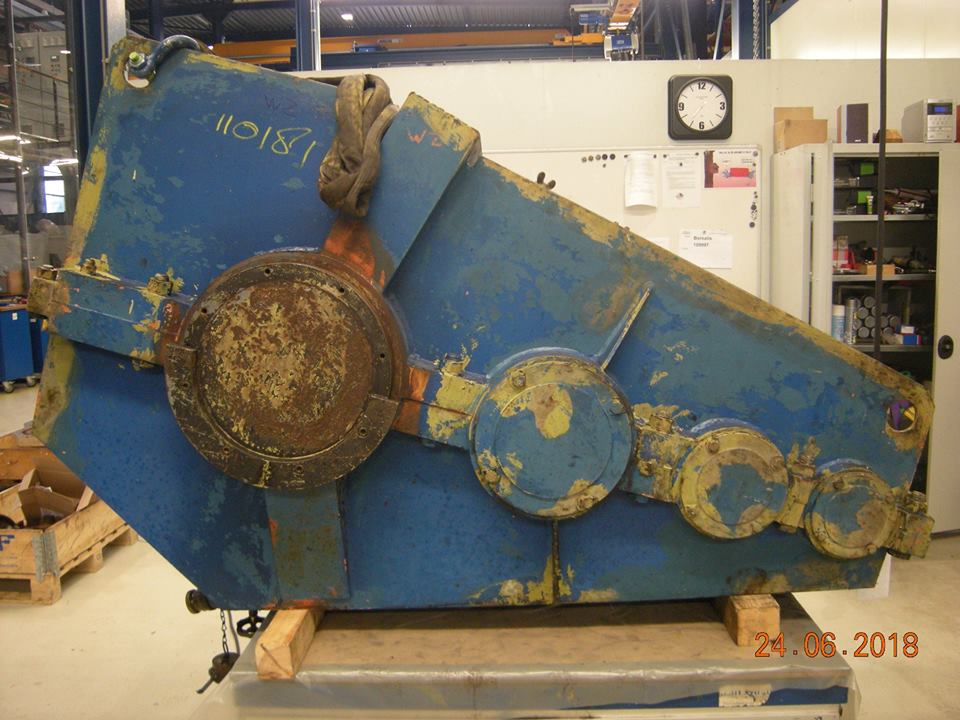

Revisie Flender double-in-single-out voorstuwingskastLees meer

Preventieve inspectie Rotterdamse havengebied PHB tandwielkastenLees meer

12 gemotiveerde studenten beginnen aan hun opleiding bij GBS TECLees meer

GBS inspecteert twee Scana Volda voortstuwingstandwielkasten in West-AfrikaLees meer

Visuele inspectie bij klant uit de voedselindustrieLees meer

GBS inspecteert 1000kW HANSEN extruder tijdens jaarlijkse shutdownLees meer

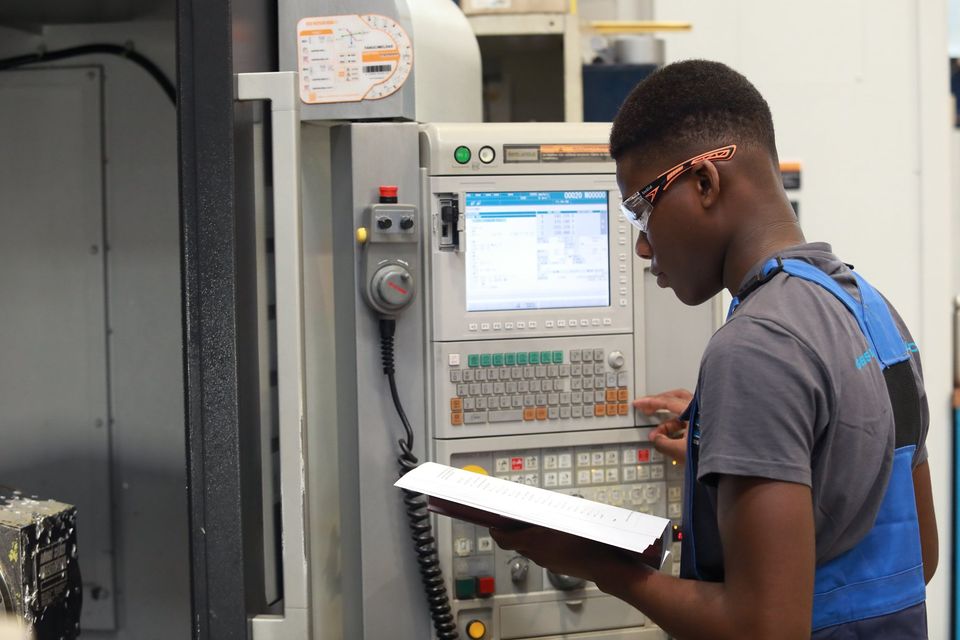

Nieuwe freesmachines van DMG MORI voor GBS TECLees meer

GBS inspecteert 10 windturbines met ZF tandwielkastenLees meer

De eerste machines voor de studenten van GBS TEC staan in bestellingLees meer

Als productiebedrijf zijnde wil je alles uit je machinepark halenLees meer

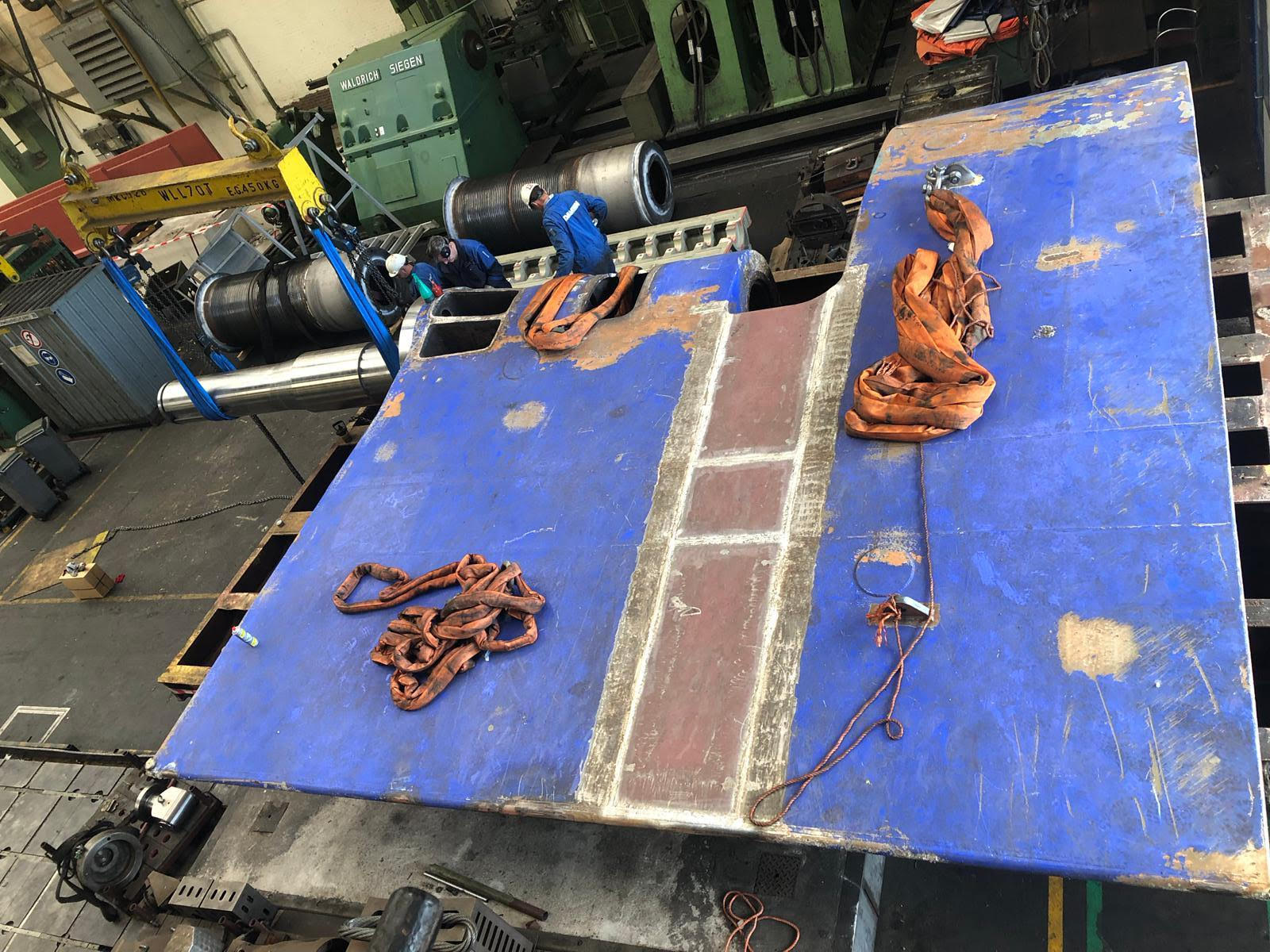

De renovatie gaat door bij GBS Machining ServicesLees meer

De metaalindustrie weer aantrekkelijk maken voor jong talentLees meer

Visuele inspectie bij klant uit de voedselindustrieLees meer

Met gepaste trots presenteren we Asset Optimization ServicesLees meer

Eerste studenten GBS TEC hebben zich ingeschreven voor de opleidingLees meer

Getting the most out of your machinery with the least amount of costsLees meer

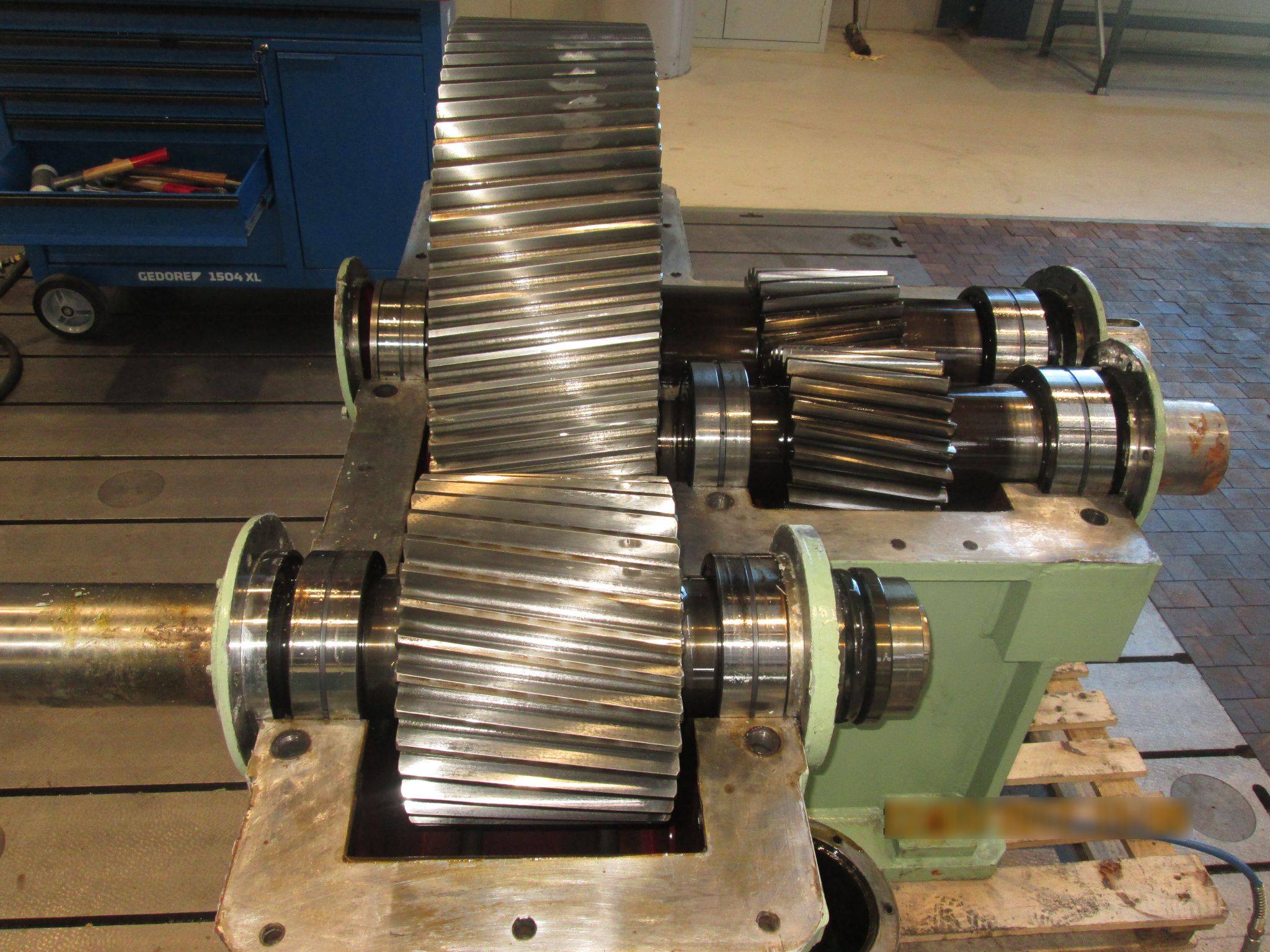

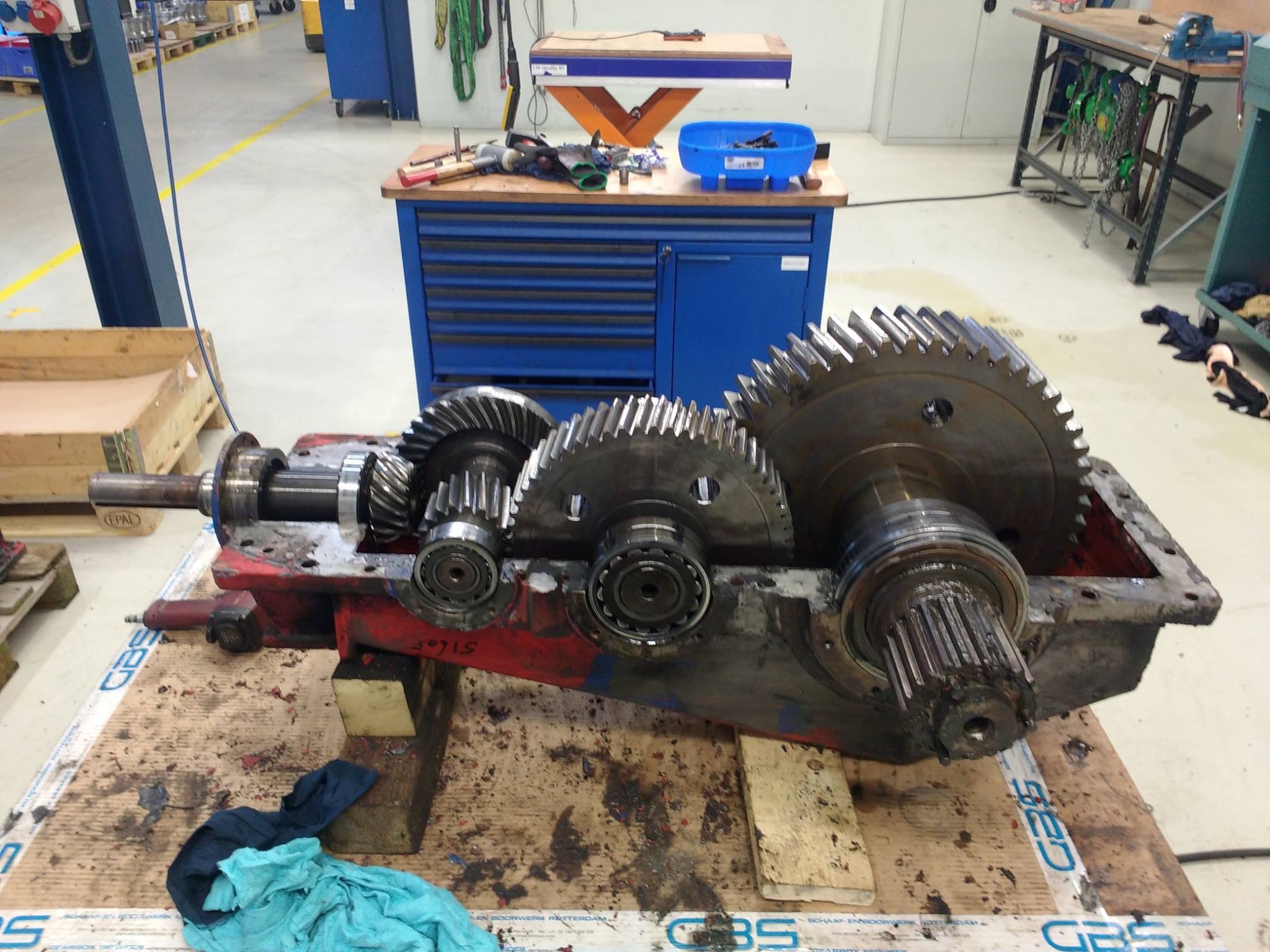

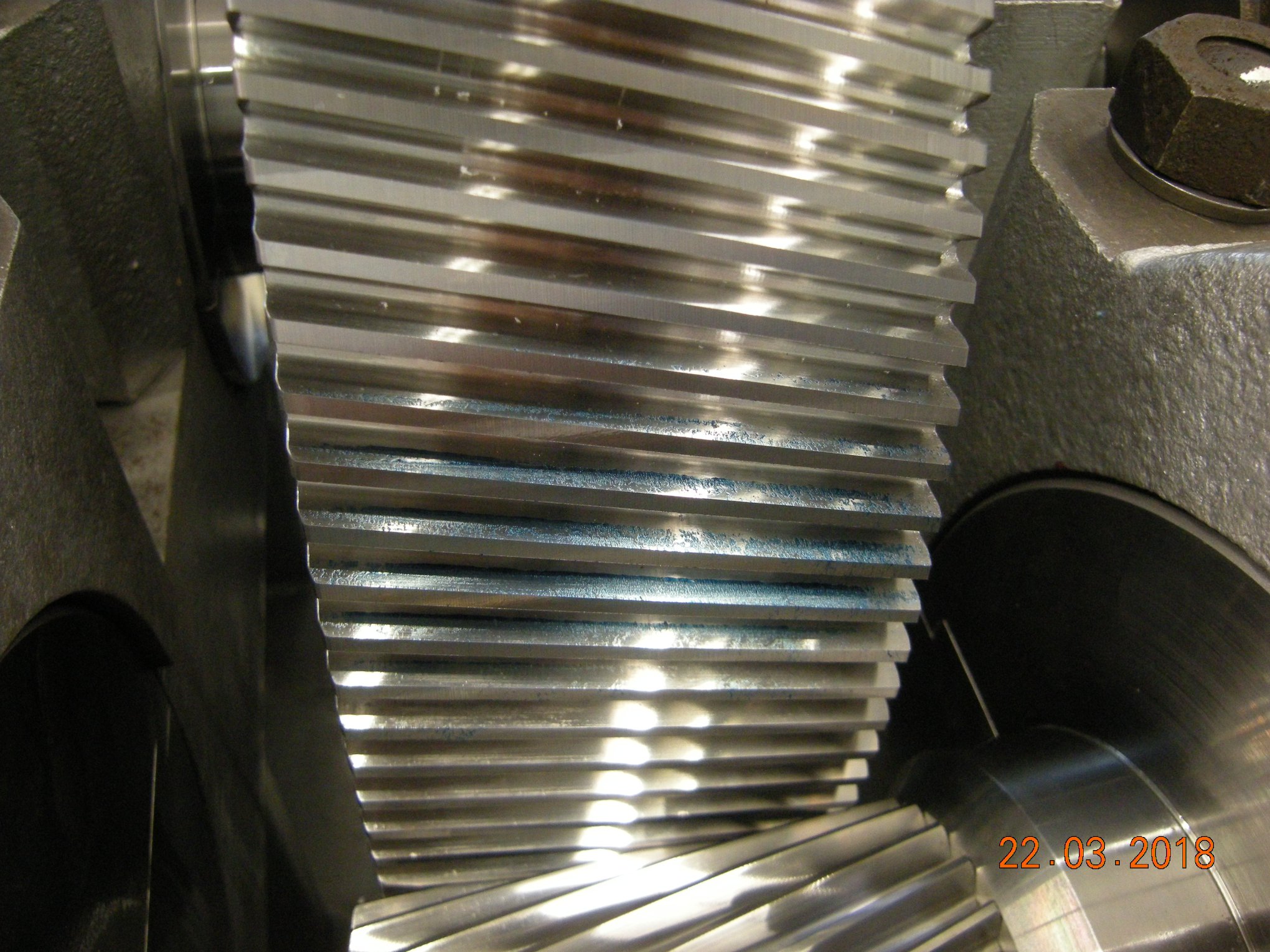

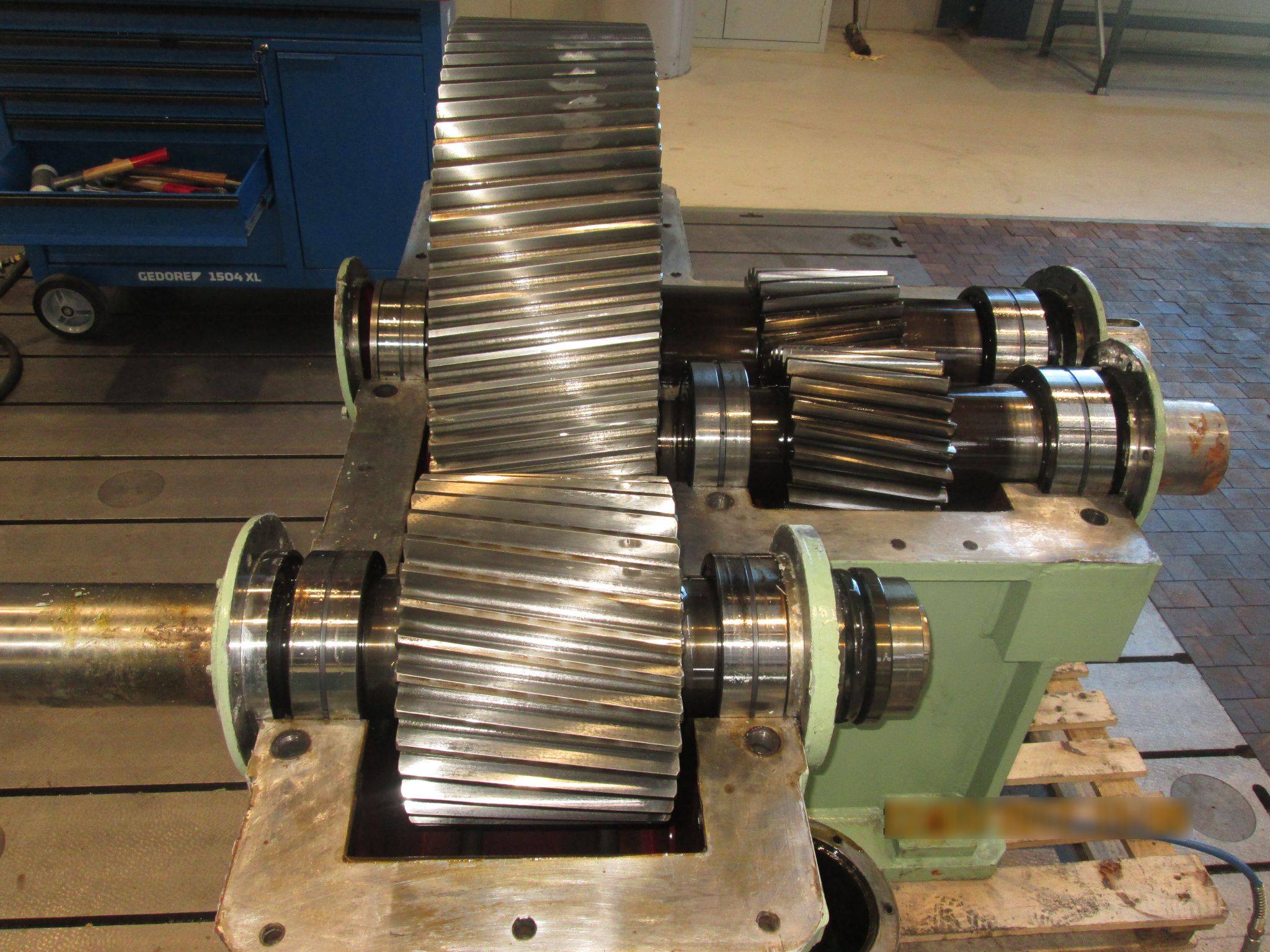

Collega's werken 24/7 aan revisie van grote tandwielkastLees meer

Leerlingen GBS TEC lager de tijd om beslissing te nemenLees meer

Leergierige jongelingen die samenwerken met ervaren collega'sLees meer

You're part of the GBS family for life - even after retiremen read more

When was the last time you were challenged to think in possibilities? read more

What do the projects look like for GBS engineers read more

All colleagues have one thing in common; passion for technology read more

One of our colleagues talks about the working atmosphere at GBS International read more

Innovate during internship at GBS International read more

New concrete floor at GBS Machining Services in Schiedam read more

GBS donates Christmas packages to elderly people at Alerimus read more

GBS was present at studentfair of Rotterdam University of Applied Sciences read more

Interns design one of the world's first hybrid engineers for a luxury sailing yacht read more

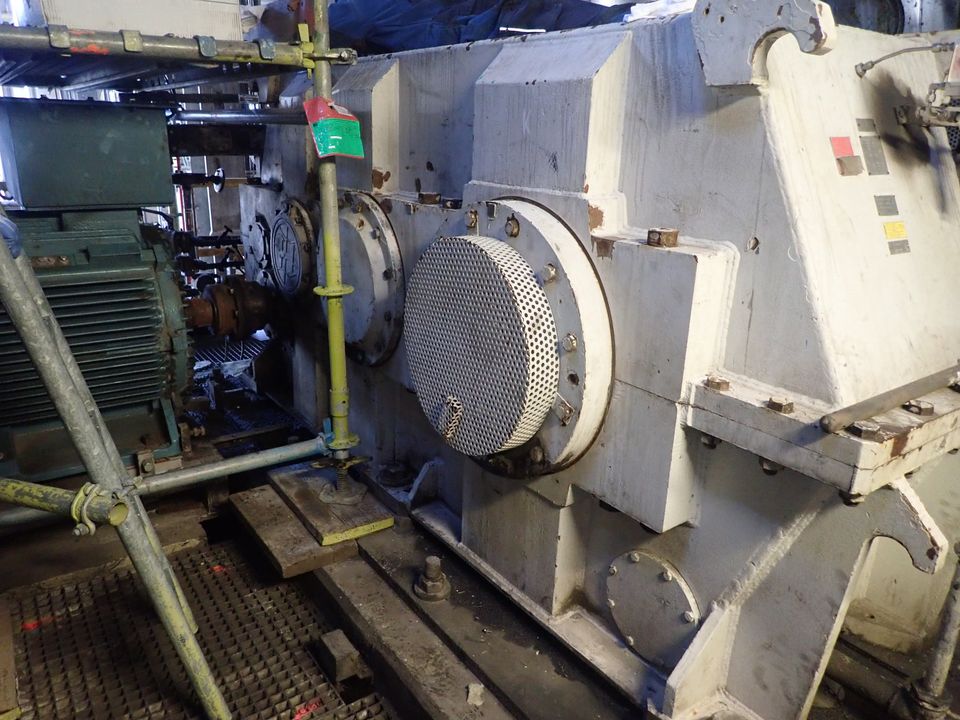

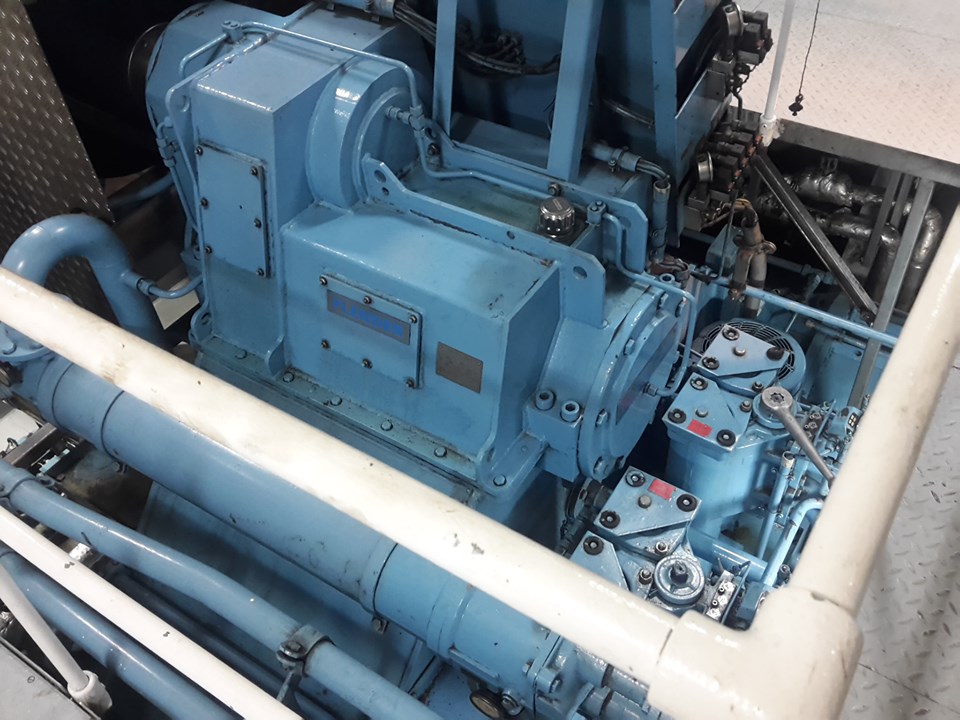

Hansen gearbox inspection and overhaul in Botlek, Rotterdam read more

Hansen gearbox inspection and overhaul in Botlek, Rotterdam read more

Gearbox inspection and overhaul to prevent gearbox failure read more

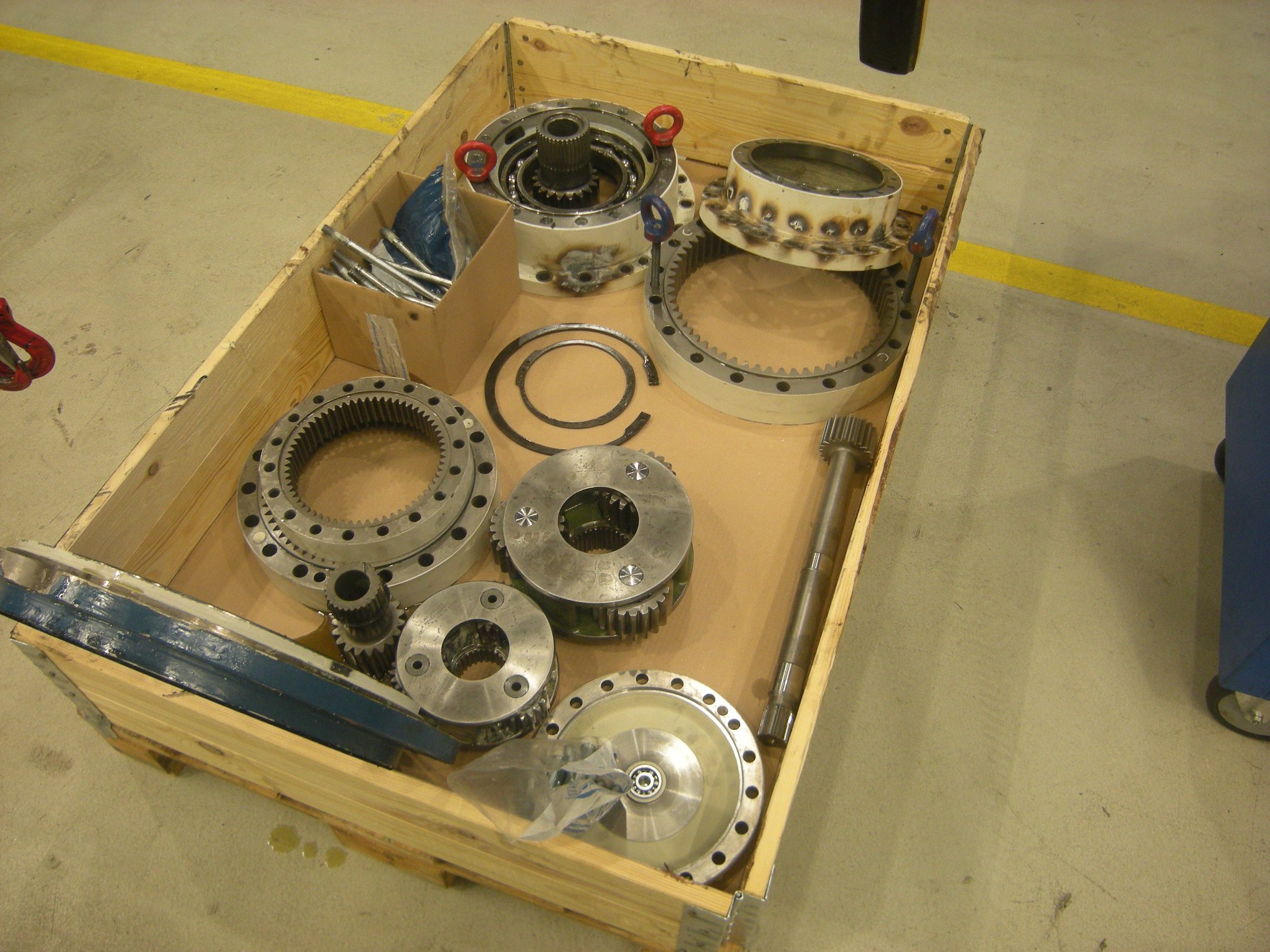

Gearbox project for one of our clients from Rotterdam Botlek area read more

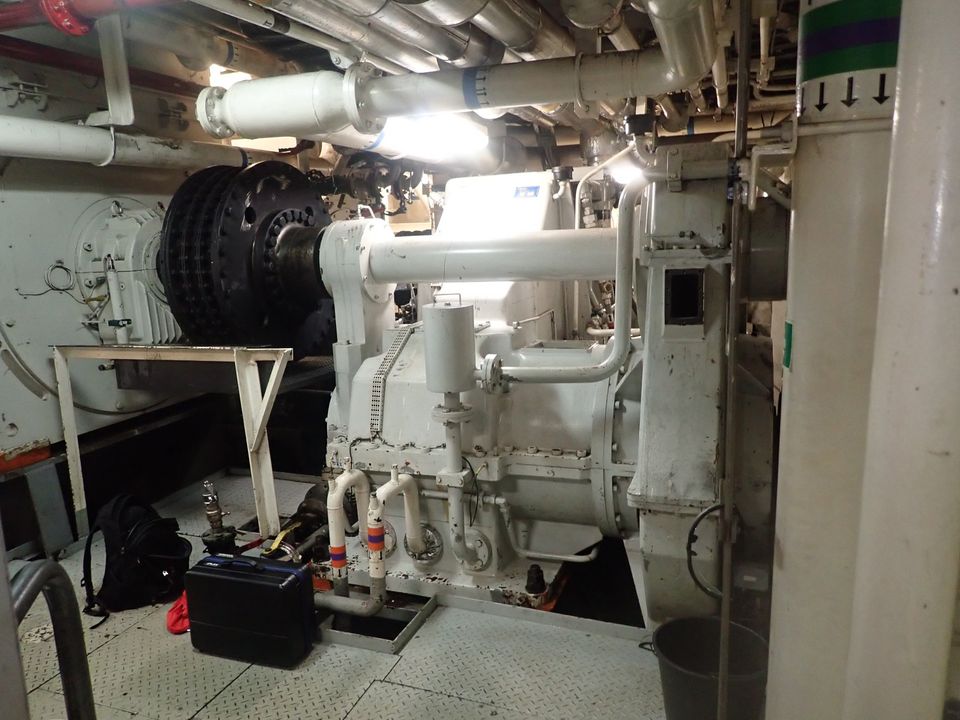

Propulsion gearbox inspection for a ship docked in Hirtshals, Denmark read more

Propulsion gearbox inspection for a container ship in Vlissingen. read more

Jahnell Kestermann gearbox repair for a client from France. read more

Sew Eurodrive gearbox project for a client from Belgium. read more

PIV gearbox repair for chemical plant in Belgium. read more

Brinkmann gearbox repair for a client from Antwerp. read more

Plenty gearbox project for a client from Europoort. read more

M.A.N gearbox repair for terminal operator in the port of Rotterdam. read more

Thyssen gearbox overhaul from client for Botlek area. read more

Gearbox project for a well-known multinational. read more

Gearbox project for terminal operator in port of Rotterdam. read more

On-site gearbox inspection for 2 wind turbines in Belgium. read more

GBS is looking for a field disgnostic engineer. read more

A recent project we did for a client from Belgium. read more

A recent project we did for a client from Rotterdam Botlek area. read more

We recently did a high speed gearbox project for a client. read more

We did an inspection and repair for a Zollern gearbox for a client from Poland. read more

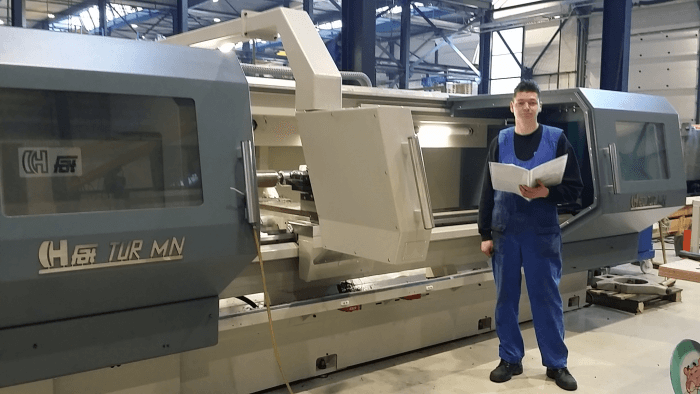

February 2017 - GBS adds new Leistritz keyseater machine and new Fathaco TUR 710 MN SERIES high-precision lathe read more

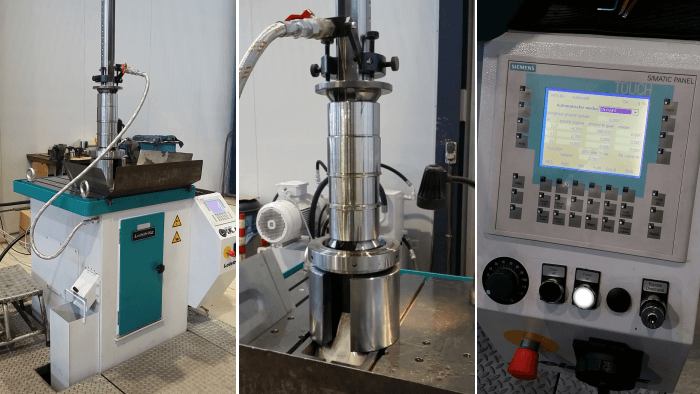

February 2017 - GBS builds new 500KW test stand for advanced gearbox load testing read more

November 2015 - GBS Gearbox Services has initiated an research and developement department for prevention of leakage of gearboxes read more

October 2015 - GBS Gearbox Services has started with it's laserclad activity read more

October 2015 - GBS Gearbox Services has started with it's laserclad activity read more

March 2015 - GBS Gearbox Services has recruited a new employee to strengthen the team of high quality gear manufacturing and bring it to the next level. read more

March 2015 - GBS has added a new technology to serve our customers faster and increase the life-time of high wearing components read more

Februari 2015 - GBS Gearbox Services International will join the High Tech Centre in Delft , read more

Januari 2015 - GBS Gearbox Services International will join the WASUB // TU Delft DreamTeam. read more

Januari 2015 - Mr. Geert Vander Schueren is representing Gearbox Services in Belgium and France, read more

In january 2015 we can serve You with on-site gear measuring. We have bought an protable 6 axes portable gear measurement tool. With this tool we can check and measure the profiles on-site of unknown gears. With this tool we have a universal, highly sophisticated and fully comprehensive 3D coordinate measuring device.

For our customers, this has the advantage that we can measure components in the gearbox. Vulnerable parts need no longer to be transported with all the risks. Gearboxes should be opened just for an short lead-time. Existing heavy gears that should be replaced, doesn't need to be transported with high costs.

In November 2014 we decided to expand our premises, which will be ready in 2015. Due to the strong growth of recent years, the existing production areas have become too full. Also a more emphatic separation of the assembly of gearboxes and the machining operations has become necessary. In addition, the new production facilty will include: a modern test stand a dirty clean room a painting room

Juli 2012 - In verband met de snel groeiende vraag van onze klanten, hebben wij in juli 2012 onze capaciteit uitgebreid met 2 draaibanken, met aangedreven gereedschappen.

Two new machines to provide an even better service

Juli 2012 – To expand our machinery department we bought two new high accuracy machines, the Mori Seiki NLX 2500Y and the PUMA 400M.

Both machines are bought to provide an extra boost to the production of gears and other related parts.

This enables us to offer our customers even more flexibility and service at any given time.

Januari 2012 - In de Hoeksche Waard zijn veel technische bedrijven gevestigd die actief zijn in de apparatenbouw, installatietechniek, technisch onderhoud etc. Al deze bedrijven maken zich zorgen over de vraag hoe ze in de toekomst aan goed technisch personeel moeten komen. Dit terwijl er op de scholen van de Hoeksche Waard zoveel slimme kinderen rondlopen die een goede boterham zouden kunnen gaan verdienen bij deze technische bedrijven. Om nu te bereiken dat er binnen de Hoeksche Waard meer bekendheid ontstaat over de technische bedrijven en het werk dat zij bieden organiseren een aantal bedrijven deze actie.

August 2011 - We have orderd a new Gear Profile Grinding Machine, the NILES ZE 800. The NILES Gear Profile Grinding machines of ZE-Series are extremely suitable for precise grinding of external and internal gears with tip diameter up to 800 mm.

August 2011 - You can follow GBS Gearbox Services international on Twitter (twitter.com/GearboxServices), Facebook (facebook.com/gearbox.services) and Youtube (youtube.com/user/gearboxservices).

July 2011 - On July 8, 2011 we have orderd two new CNC machining centers. The 3-axis NVX5100 and the price winning 5-axis NMV8000 will be added to our workshop. Both machines are of the brand Mori Seiki and will be used to fabricate gears. The machines will be operated by our employee Adjinder Leda.

See video

Jan. 2010 - The total repair costs and lead times are also determined by the logistical operations on site. If our customers do not have a regular supplier for total maintenance or for the on-site logistics, we can advise you with this. Furthermore, we want long term relationships with wind turbine maintenance companies to exchange the right practical data to obtain information on the performance of wind turbine gearboxes, thereby continuing to work on new improvements and modifications.

Nov. 2009 - Since initiating our gearbox services, and the subsequent strong growth of our business, we have decided to change our brand name into Gearbox Services International (abbreviated GBS International). Our machining activities will keep the name of Schaaf- en Boorwerk Rotterdam.

Nov. 2009 - Our long experience in windturbine gearbox inspections is now as a new activity in our company, approved by PMP.

Oct. 2009 - See where we are working this moment. (picture right is just an example, click link for real-time-jobs)

Sept. 2009 - Customers from abroad have to rely on paper and on our word. Confidence should also be actively encouraged by us. We want to be an trustfull open company. We will introduce soon for our foreign clients, on a secure site, the progress of their projects through daily update pictures, papers etc. This service is free and not mandatory but is just at your disposal.

Sept. 2009 - GBS Gearbox Services international have recruited a team who has already performed many inspections on wind turbines. They have also inspected wind farms located all over Europe. Our team has worked for energy companies, insurance companies, windmill suppliers and independent service companies. We are now able to offer these forms of inspections by our company.

Sept. 2009 - Starting from 1 october 2009 Mr. Marc de Bleser will start with our company. He will do the acquisitions in Belgium and the North of France for aswell gearbox inspections, diagnostcs and repair as machining of components in our factory.

Aug. 2009 - In August we have acquired a new machine with high accuracy for the production of spline and other gears production. In September this machine was operational.

Aug. 2009 - Today we have formed our new team for onsite diagnostic services. Mr Arjan Visser and Walter Bonnier will after many years of experience in Stork Gears & Services BV join our company. This allows our customers to get the highest level in vibration measurements, torque measurements, geometric alignments, troubleshooting, commissioning, inspections and hands-on services.

July 2009 - Today we placed an order for further automation of production of small parts. Although we are focussing in our strategy on large parts, we regularly have smaller complex parts in order. To this end, we take steps in a flexible automated handling of materials and finished products. The delivery will take place in September 2009. This robot will be operational in sept.

July 2009 - As of August 1, 2009, the gentlemen M. Opstal and T.van Frijters will enter employment at SB. Both gentlemen have extensive experience in Stork Gears & Services BV on the field of machining of parts of gearboxes and inspection, repair, and assembly of gearboxes. In this way Schaaf- en Boorwerk Rotterdam BV will increasingly invest in personnel for the new activity of Gearbox Maintenance, which will start by September 1, 2009.

June 2009 - In June 2009, Mr. Vincent van Ede will be employed. Following his broad experience in Stork Gears & Services BV, he will be responsible within our company for the renewal of our machines base on the latest techniques, including the manufacture of gears.

Nov. 2008 - In the months October and November, we expanded our service scope to align-and flatness measurements.

Sept. 2008 - In the months August and September have strengthened our organization. Besides a number of skilled workers in our factory, we could attract a number of experienced staff for workpreparation / sales and engineering.

July 2008 - On July 3, 2008 we have ordered a Heavy Duty Turning Center PUMA 700LM. With this we have put a first step in the improvement and expansion of our turning operations.